Introduction

In the vast landscape of plastic manufacturing, few processes have left as indelible a mark as the vacuum forming method. This intricate technique has revolutionized the way we shape and mold plastic, giving rise to a myriad of everyday objects that we often take for granted. As we embark on this journey through the world of vacuum forming, our spotlight turns towards a captivating juxtaposition: the difference between one-piece and multi-piece vacuum formed parts. These two approaches, though born from the same innovative process, possess distinct qualities that shape their applications and outcomes. In this article, we delve into the heart of this dichotomy, unraveling the intricacies that set them apart, and exploring the unique advantages and applications that each brings to the table. Join us as we navigate the realm of vacuum forming, peeling back the layers to reveal the fascinating world of one-piece and multi-piece vacuum formed parts.

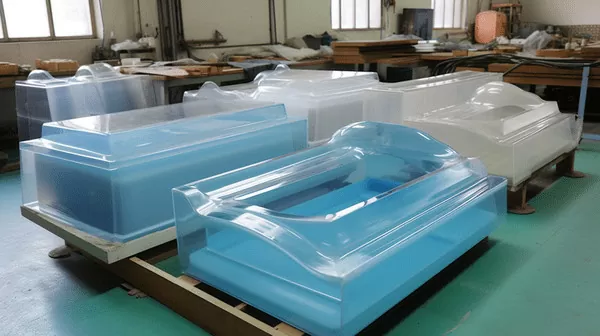

I. One-Piece Vacuum Formed Parts: Seamless Simplicity

A. The One-Piece Vacuum Forming Process

In the realm of vacuum forming material, the one-piece approach stands as a testament to elegant simplicity. This method, like a symphony in plastic manipulation, begins with a single mold and a pliable plastic sheet. As the plastic sheet is gently heated, it transforms from rigidity to malleability, ready to take on its destined form. The stage is then set for the enchanting act of vacuum pressure forming. Like a master conductor, the vacuum pump orchestrates the dance, drawing the air away and coaxing the heated sheet to embrace the mold's contours. The result is nothing short of magical – a seamless, continuous piece that holds the promise of functional and aesthetic excellence.

B. Advantages of One-Piece Parts

The allure of one-piece vacuum formed parts lies not only in their manufacturing elegance but also in the inherent benefits they bring to the table.

1.Simplicity in Design and Manufacturing:

One-piece parts bestow the gift of uncomplicated design and manufacturing processes. With a single mold and minimal assembly requirements, the path from concept to creation is streamlined, allowing for efficient production and reduced complexity.

2.Structural Integrity of a Single, Unbroken Piece:

A hallmark of one-piece parts is their robust structural integrity. The absence of seams or joints ensures a cohesive and sturdy construction, translating to enhanced durability and reliable performance.

3.Aesthetic Appeal with No Visible Seams or Joints:

The visual charm of one-piece vacuum formed parts is hard to ignore. The absence of visible seams or joints grants them a seamless and polished appearance, elevating the overall aesthetic appeal of the end product.

C. Considerations

While the allure of one-piece vacuum formed components is undeniable, it's essential to acknowledge the considerations that come into play.

Challenges with Intricate Designs:

The one-piece approach, while elegant, might pose challenges when it comes to intricate and complex designs. Parts with convoluted geometries or intricate details may be better suited for alternative methods.

Potential Complexities in Mold Development:

As the foundation of the process, mold development plays a pivotal role. In the case of one-piece parts, creating molds for certain designs could introduce complexities that require careful planning and investment.

The realm of one-piece vacuum formed parts offers a harmonious blend of simplicity, durability, and visual appeal. It stands as a testament to the ingenuity of vacuum forming, offering a glimpse into a world where a single mold and a pliable plastic sheet can weave wonders of design and functionality.

II. Multi-Piece Vacuum Formed Parts: Assembling Complexity

A. The Multi-Piece Vacuum Forming Process

The multi-piece vacuum forming process takes the stage as a dynamic symphony of plastic transformation, introducing a captivating interplay of molds, plastic sheets, and assembly.

1.Introduction to Multi-Piece Vacuum Forming:

Imagine a choreographed dance of creativity and engineering. Multi-piece vacuum the pressure forming process commences with an ensemble of multiple molds and plastic sheets, each awaiting their moment to shine.

Use of Multiple Molds and Plastic Sheets:

Unlike its one-piece counterpart, multi-piece vacuum forming technique orchestrates a harmonious collaboration between various molds and plastic sheets. Each sheet, heated to pliability, takes on a distinct form, and together they weave a tale of complexity.

Individual Forming and Later Assembly of Parts:

The magic unfolds as individual pieces are formed with precision, each destined for a specific role. The climax arrives during assembly, where these meticulously crafted pieces join forces to shape the final product.

Enabling Complex Designs and Greater Flexibility:

Multi-piece vacuum formed parts unlock the realm of intricate designs and limitless possibilities. Complex shapes, interlocking components, and multifaceted features emerge with finesse, fulfilling even the most demanding design aspirations.

B. Advantages of Multi-Piece Parts

The allure of multi-piece vacuum formed parts lies in their ability to transcend limitations and embrace innovation.

Design Flexibility for Intricate Shapes and Features:

Multi-piece parts are the canvas of creativity. They allow for the manifestation of intricate designs, granting designers the power to craft forms that push the boundaries of imagination.

Ease of Production and Potential Cost Savings through Assembly:

In the grand tapestry of manufacturing, multi-piece parts offer a unique advantage—efficiency. Individual parts can be formed at optimal conditions, reducing material waste and enabling potential cost savings through streamlined production.

Economical Tooling Compared to Intricate Single Molds:

The stage is set for economic ingenuity. Mold development for multi-piece parts can be less intricate and costly compared to the creation of plastic components from a single complex mold, making it an attractive proposition for cost-conscious endeavors.

C. Considerations

As with any production method, the multi-piece approach presents its own set of considerations.

Assembly Time as an Additional Step:

The orchestration of multi-piece parts involves an additional step—assembly. While this step may introduce a slightly extended production timeline, the end result often justifies the investment of time.

Impact on Aesthetics Due to Potential Visible Seams or Joints:

Aesthetic considerations come to the forefront when dealing with multi-piece parts. Depending on the precision of assembly, visible seams or joints may be present, potentially impacting the final visual aesthetics.

In the realm of multi-piece vacuum formed parts, the allure of complexity intertwines with the practicality of assembly. It's a testament to the versatility of vacuum forming—a canvas where creativity knows no bounds and innovation takes center stage. As we peel back the layers of this captivating process, the synergy of multiple molds and plastic sheets reveals a world where intricate designs and practical production coexist in harmony.

III. Comparing One-Piece and Multi-Piece Vacuum Formed Parts

A. Key Differences and Benefits

In the grand tapestry of vacuum forming machines, the juxtaposition between one-piece and multi-piece parts paints a vivid picture of versatility and innovation.

1.Advantages of One-Piece Parts:

The allure of one-piece vacuum formed parts lies in their simplicity and structural integrity. These advantages encompass:

Streamlined Design and Manufacturing: One-piece parts boast a streamlined journey from conception to creation, offering an efficient route to production.

Robust Structural Integrity: The absence of seams or joints ensures these parts possess a single, unbroken structure, translating to enhanced durability.

Sleek Aesthetic Appeal: With no visible seams or joints, one-piece parts present a polished appearance that seamlessly blends into various settings.

2.Benefits of Multi-Piece Parts:

The world of multi-piece vacuum formed parts embraces the art of complexity, offering unique attributes such as:

Design Flexibility Beyond Boundaries: Multi-piece parts are a playground for intricate designs and complex geometries, unleashing the potential for innovation.

Efficient Production and Cost Savings: Through individual forming and assembly, multi-piece parts optimize material usage and offer potential cost advantages.

Economical Tooling for Varied Designs: The whole injection molding landscape for multi-piece parts can often be less intricate and more cost-effective, facilitating a range of designs.

Considering Project Alignment: The choice between one-piece and multi-piece vacuum formed parts hinges on project requirements. It's a delicate balance of factors like design intricacy, production efficiency, cost, and intended aesthetics. Selecting the suitable approach ensures the final product aligns seamlessly with project goals.

B. Application Examples

As the spotlight shifts to real-world applications, the prowess of one-piece and multi-piece vacuum formed parts takes center stage.

1.One-Piece Parts Excel In:

Food Packaging: The streamlined design of one-piece parts makes them an ideal candidate for food storage containers, ensuring hygiene and practicality.

Consumer Goods: Items like plastic boxes and rigid containers often benefit from the simplicity and sleek aesthetics of one-piece parts.

2.Advantages of Multi-Piece Parts Shine In:

Automotive Industry:

Multi-piece parts can tackle the complexity of automotive interiors, offering a canvas for intricate designs and functional integration.

Medical Equipment:

Multi-piece parts can facilitate the creation of medical devices with interlocking components, providing both precision and utility.

3.Real-World Applications Across Industries:

Construction Equipment:

Multi-piece parts find their calling in crafting skid plates and components that demand durability and intricacy.

Lighting Solutions:

One-piece parts contribute to light diffusers, while multi-piece parts enable the construction of intricate light fixtures.

In the grand tapestry of vacuum forming, the choice between one-piece and multi-piece parts is a narrative of design ingenuity and practical application. Each approach brings its unique strengths to the forefront, offering a diverse toolkit for manufacturers and designers to shape the world around us. As we navigate the intricate web of possibilities, we find ourselves at the intersection of innovation and functionality, where the synergy of design and production unfolds in the realm of vacuum formed parts.

As we draw the curtains on our exploration, the world of vacuum forming reveals itself as a realm where innovation and practicality intertwine. The journey through the distinctions between one-piece and multi-piece vacuum formed parts has unveiled a tapestry of creativity and engineering finesse, each approach bearing its unique mark on the landscape of plastic manufacturing.

Throughout this expedition, the pivotal role of design, production efficiency, aesthetics, and cost considerations has shone brightly. The choice between one-piece and multi-piece parts is not merely a matter of technique, but a strategic decision that shapes the very essence of a project. The canvas of design is painted with precision, with each stroke representing the delicate balance between form and function.

Informed decision-making emerges as the guiding star in this narrative. As architects of plastic possibilities, manufacturers and designers are empowered to steer their projects with clarity and purpose. By aligning the chosen approach with project goals and requirements, they harness the full potential of vacuum forming to breathe life into plastic visions.

Conclusion:

As we step back to admire the grand tableau of vacuum forming, a symphony of possibilities resonates. From food packaging to medical equipment, automotive components to lighting solutions, vacuum forming transcends boundaries, crafting a world where plastic part visions find vibrant expression. It is a nod to the intricate dance of technology and artistry, a salute to the ever-expanding horizons of innovation.

So, whether you seek the elegance of seamless simplicity or the complexity of assembled masterpieces, vacuum forming stands ready to bring your plastic part dreams to fruition. As the curtain falls on this exploration, we leave you with an invitation to embrace the myriad possibilities that vacuum forming offers—a world where plastic takes on form, function, and a touch of magic.