As a multi-process plastic manufacturer, ZetarVac integrates Thermoforming, Extrusion, and Blow Molding to deliver diverse industrial solutions. We provide the ideal manufacturing path for everything from structural enclosures to specialized tubing.

Rapid prototyping and full-scale mold production (150+ sets/month) ensuring speed-to-market for all three core processes.

Specializing in large-scale vacuum forming for industrial enclosures, medical device covers, and structural panels with complex geometries.

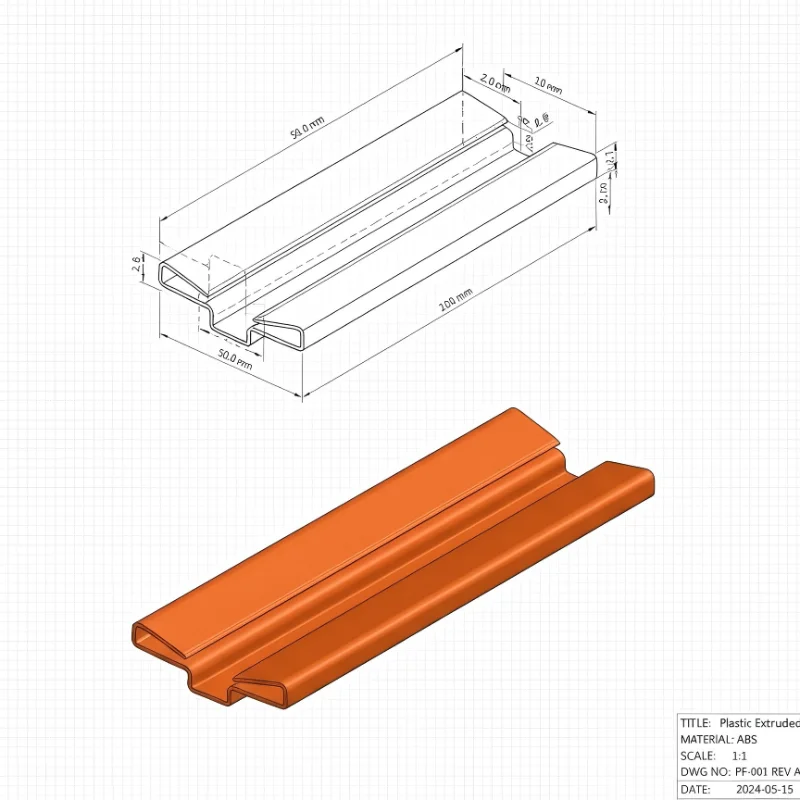

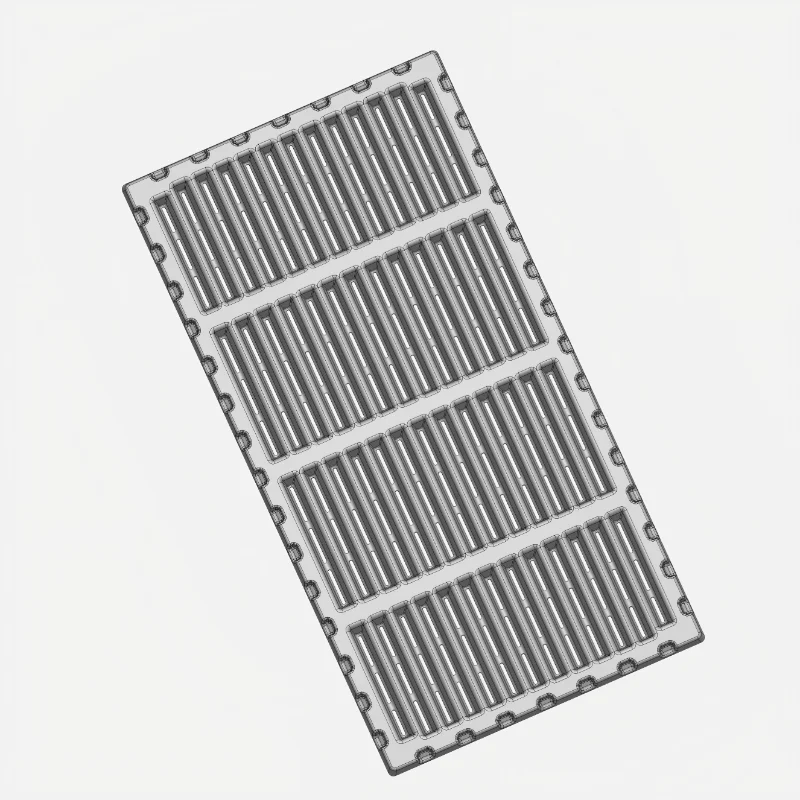

Precision manufacturing of rigid and flexible profiles, industrial tubing, and custom channels with complex cross-sections.

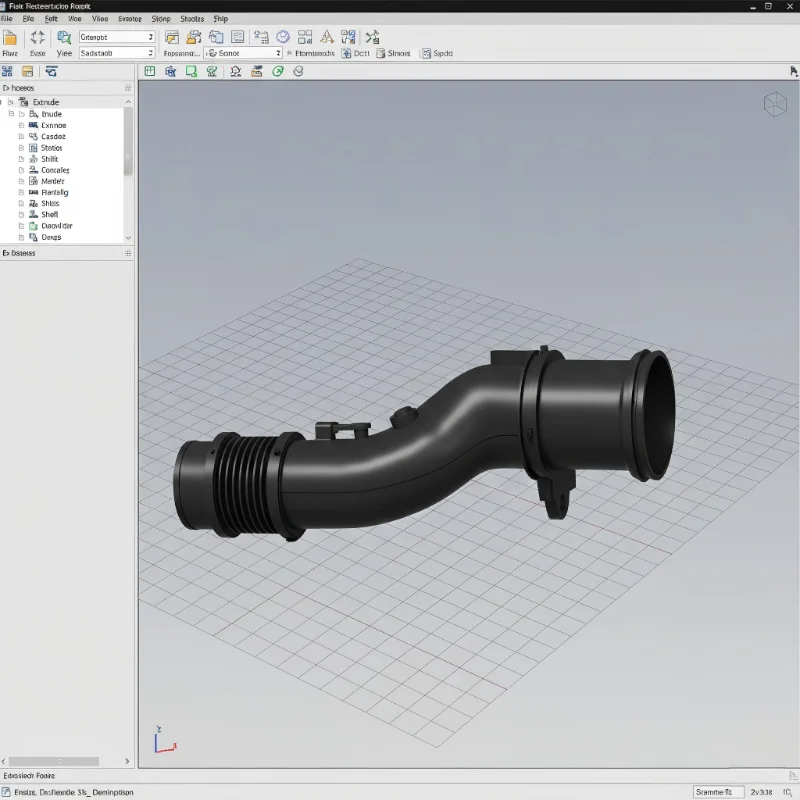

High-volume production of large hollow parts, custom tanks, and robust double-walled structures for automotive and machinery.

We have helped numerous clients achieve their goals with our tailored solutions across Thermoforming, Extrusion, and Blow Molding.

Protective covers & engine housings

Seat shells & cabin interiors

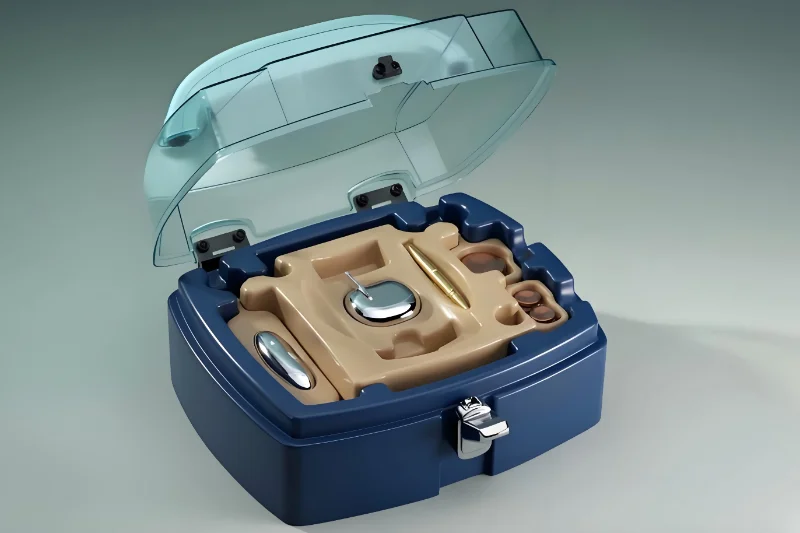

MRI & CT scanner enclosures

Bus & rail interior panels

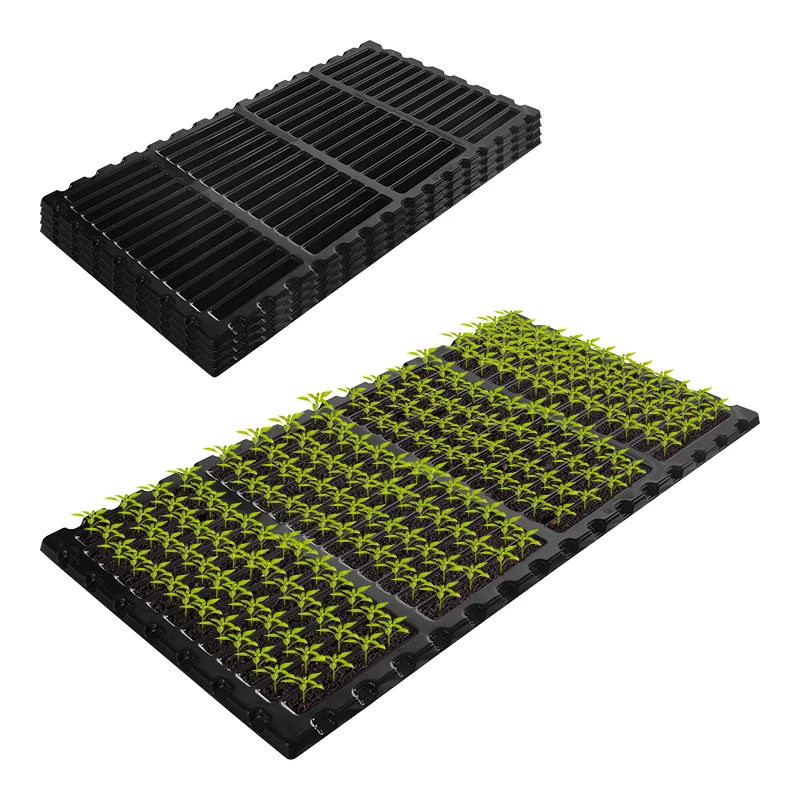

Growing trays & hydroponic systems

Dashboard panels & door trims

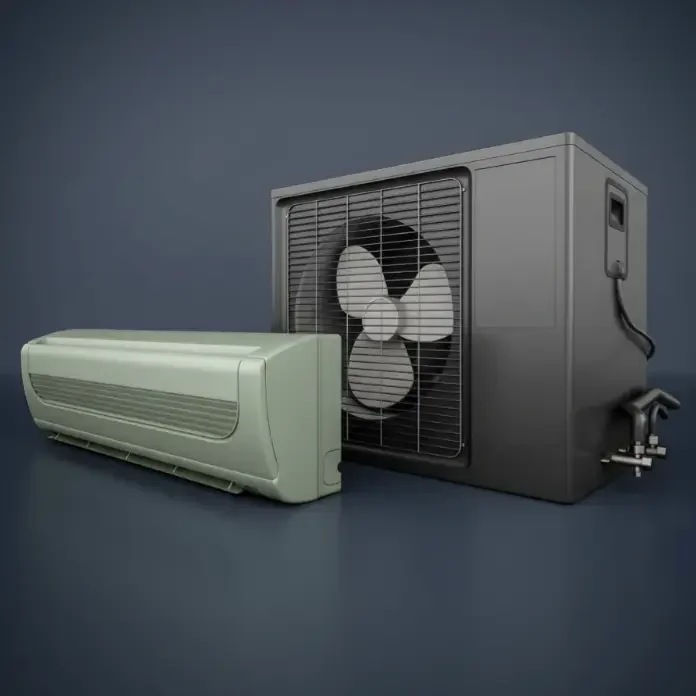

Duct housings & air handler covers

Processing equipment & storage trays

From initial concept to global logistics, we provide integrated manufacturing solutions across Vacuum Forming, Extrusion, and Blow Molding, delivering high-precision components for diverse industrial applications.

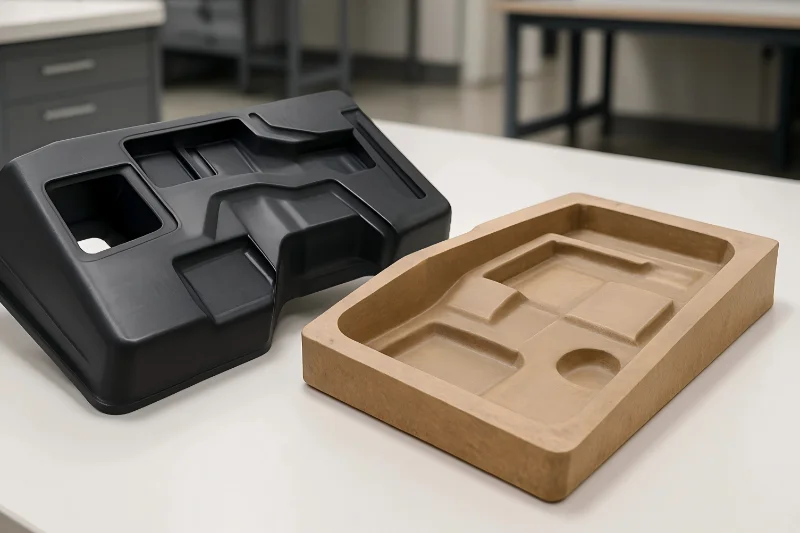

Validate Designs Before Mass Production. We offer fast-turnaround prototype development using advanced 3D printing and temporary tooling. This allows you to validate designs, test fitment, and refine functionality before committing to full-scale production tooling.

Precision Tooling for Long-Term Reliability. Our engineering team utilizes CAD/CAM software to design and fabricate custom aluminum and steel molds. We ensure every tool is optimized for high-volume production across all molding and extrusion processes.

Versatile Solutions for Custom Plastic Parts. We integrate three core processes: Vacuum Forming for large-scale parts, Plastic Extrusion for continuous profiles, and Blow Molding for hollow structures. We select the optimal method based on your specific requirements.

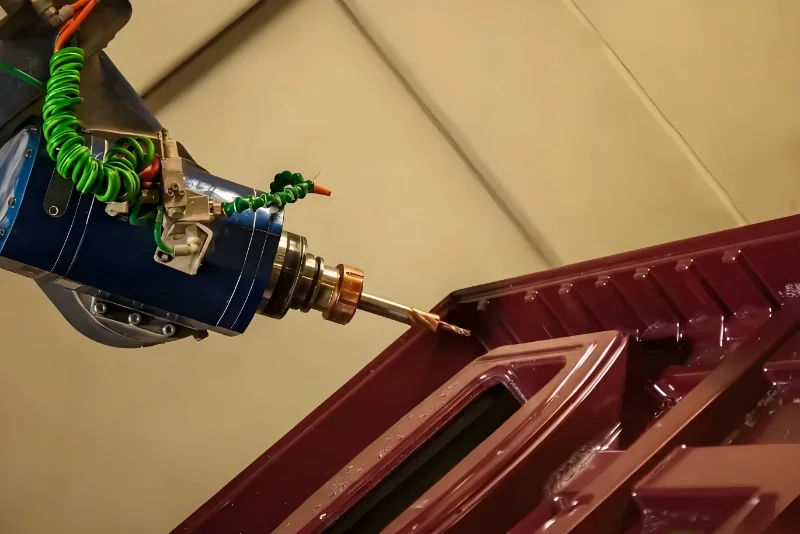

Precision Secondary Operations for Perfection. We provide comprehensive finishing services, including 5-axis CNC trimming for complex shapes, precise cutting for extrusions, and professional deburring. We guarantee tight tolerances and clean edges that meet your exact drawings.

Integrated Solutions for Ready-to-Use Units. Beyond molding, we offer full sub-assembly services such as hardware installation, ultrasonic welding, and bonding. Every component undergoes rigorous quality testing to ensure it arrives at your facility ready for immediate installation.

Secure Packaging and Worldwide Delivery. We provide specialized packaging for large-format and fragile components. Our team coordinates custom crating and global freight services, ensuring your products are tracked and delivered safely to any destination on schedule.

Ready to discuss your custom plastic project? Whether you need thermofroming & vacuum forming, extrusion molding, or blow molding, our engineering team is standing by to provide a technical consultation and a competitive quote.

Request QuoteOur streamlined workflow ensures precision at every step, from initial consultation to final quality assurance and shipping.

We analyze your requirements, discuss material options, and create detailed CAD designs with engineering specifications.

Precision mold fabrication using CNC machining, followed by prototype production for form, fit, and function validation.

Full-scale precision production with CNC trimming, assembly, and finishing operations in our controlled environment.

Comprehensive quality inspection, dimensional verification, and secure packaging for on-time delivery to your facility.

High-speed automated forming

Rapid tooling capability

Step inside ZetarVac's factory. We combine massive capacity with engineering precision to deliver thermoforming & vacuum forming, extrusion molding, blow molding solutions for Aerospace, Medical, and Industrial sectors.

Certified Quality Standards

We bridge the gap between prototyping and high-volume injection molding with robust thick-gauge thermoforming solutions.

We provide expert vacuum forming, extrusion, and blow molding services, managing your entire project from start to finish.

Specializing in Kydex, Polycarbonate, ABS, and HDPE. We deliver parts that withstand impact, chemicals, and extreme temperatures.

We offer full assembly and specialized packaging services, ensuring your components arrive finished and ready for distribution.

We simplify international trade with DDP shipping terms. From customs clearance to final delivery, we ensure your molds and parts reach 30+ countries safely.

Zero language barriers. Our project managers combine engineering expertise with fluent English, bridging the gap between your design team and our production floor.

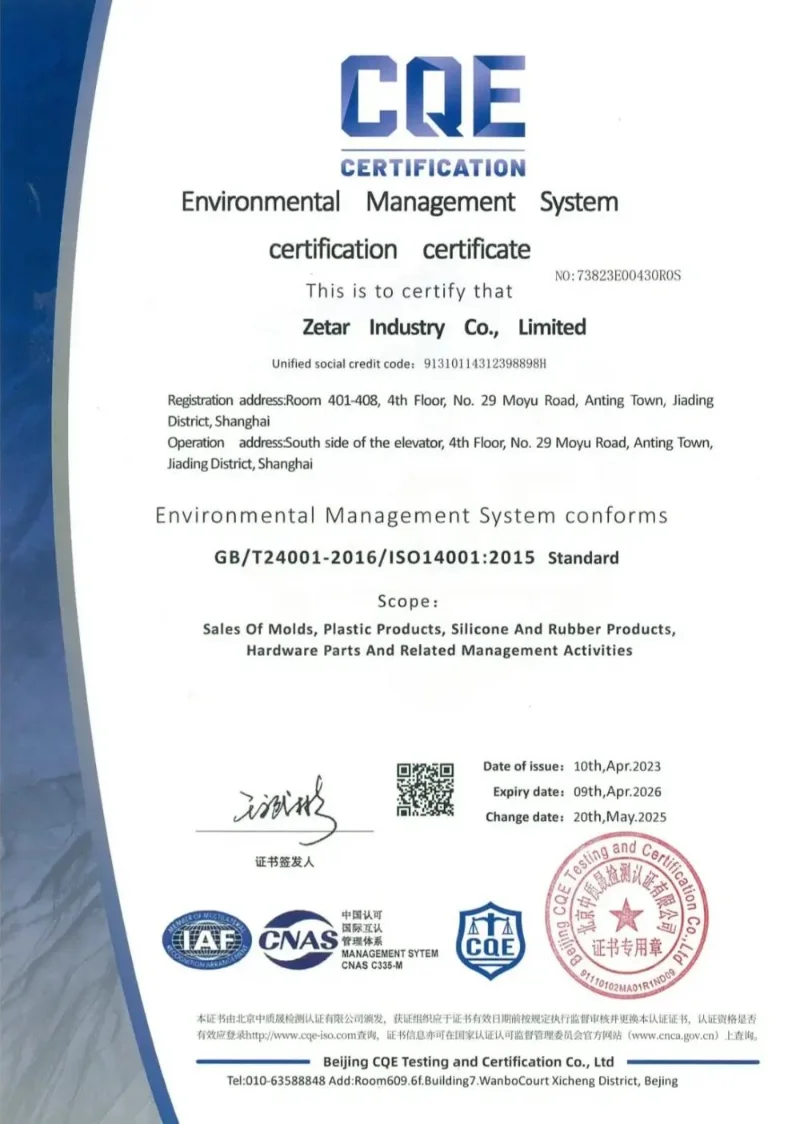

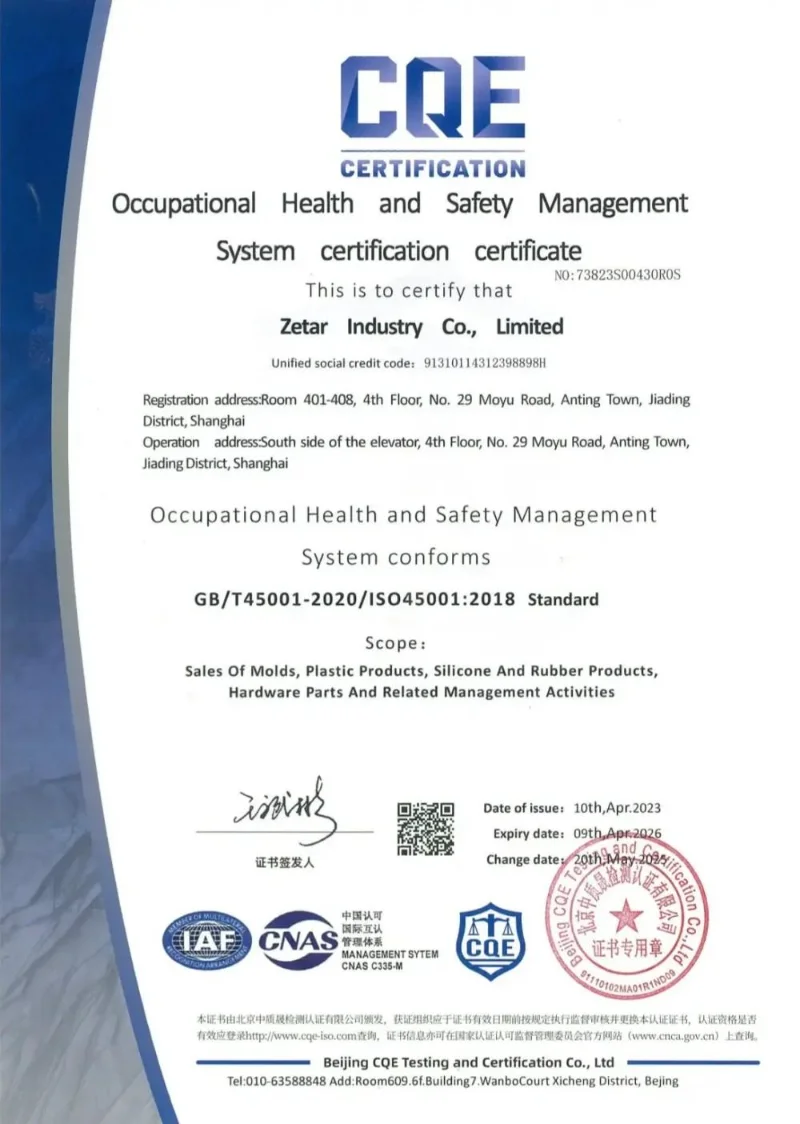

Manufacturing to international standards. With ISO 9001 & 13485 certifications, we provide the traceability and consistency required by global supply chains.

ZetarVac's advanced manufacturing capabilities and industry certifications ensure the highest quality standards for mission-critical applications.

Quality Management System

Medical Device Quality

Environmental Management

Occupational Health & Safety

From initial design consultation to large-scale thermoforming production, ZetarVac is your partner for heavy-gauge plastic components.

Get a free engineering consultation and custom quote. Our team delivers comprehensive solutions within 48 hours.