Custom Plastic Parts On-Demand Manufacturing

As a multi-process plastic manufacturer, ZetarVac integrates Thermoforming, Extrusion, and Blow Molding to deliver diverse industrial solutions. We provide the ideal manufacturing path for everything from structural enclosures to specialized tubing.

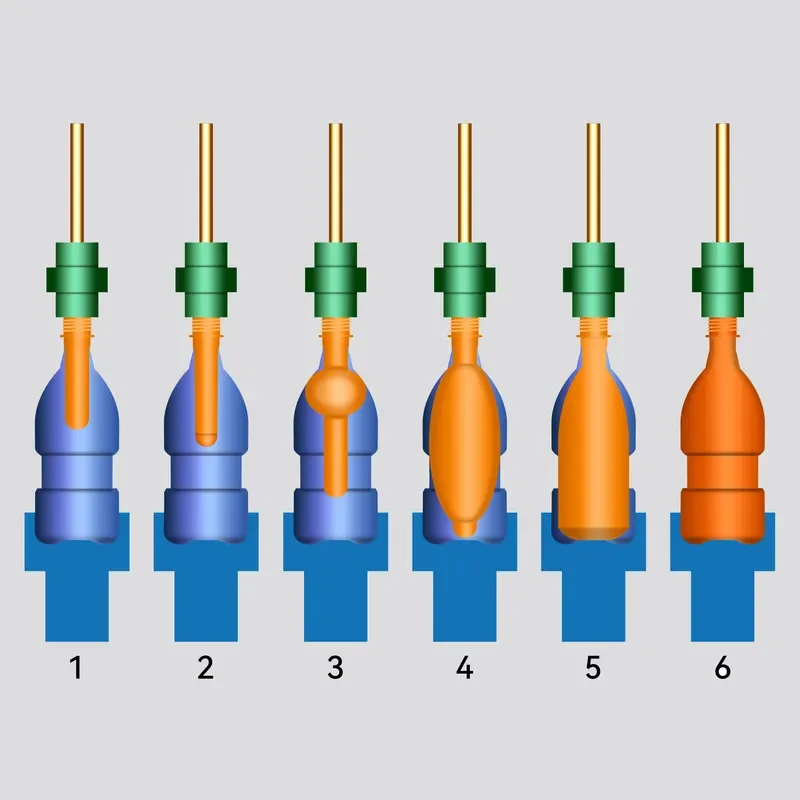

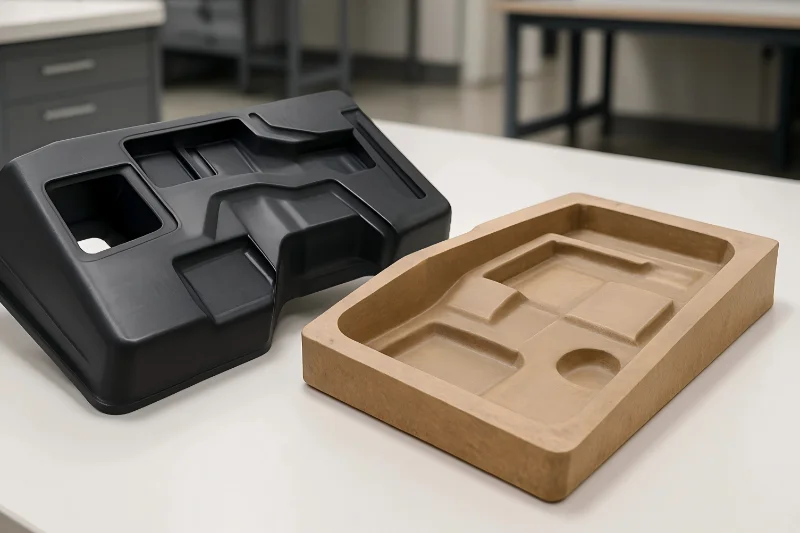

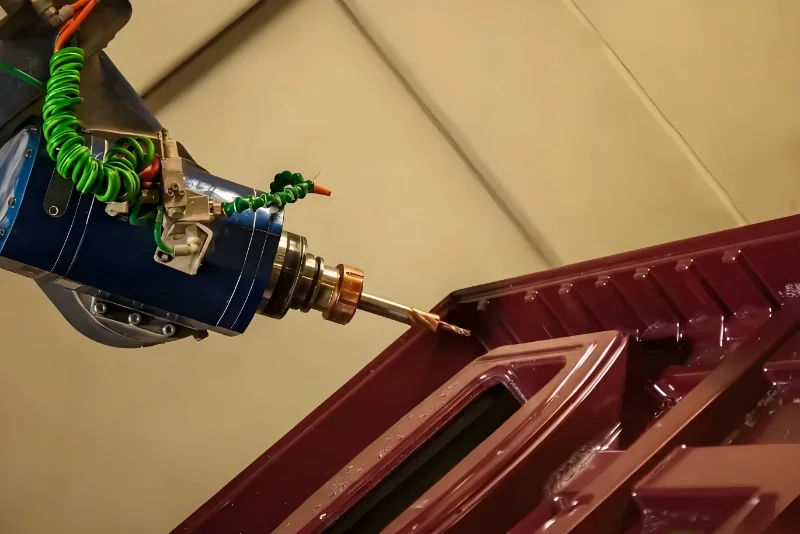

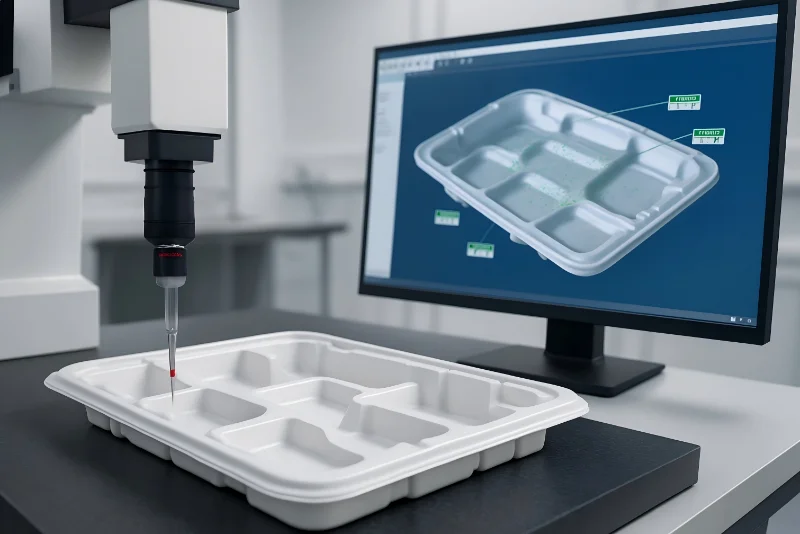

Mold & Tooling Mnufacturing

Rapid prototyping and full-scale mold production (150+ sets/month) ensuring speed-to-market for all three core processes.

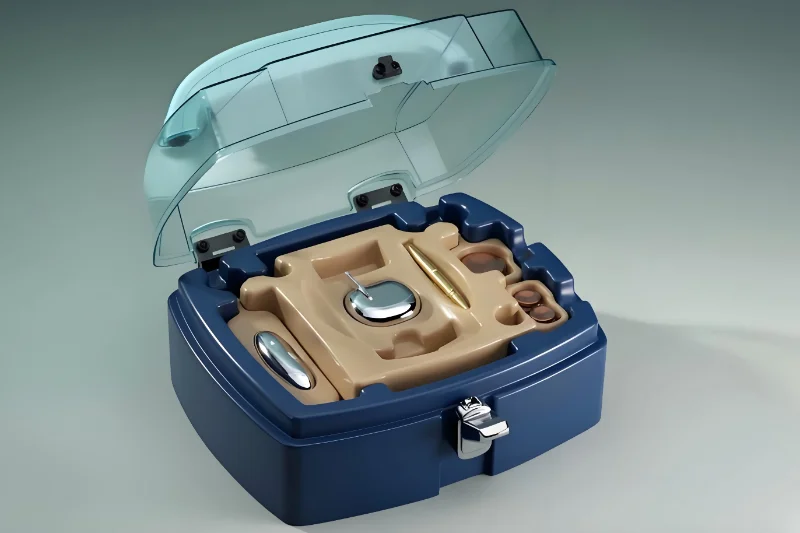

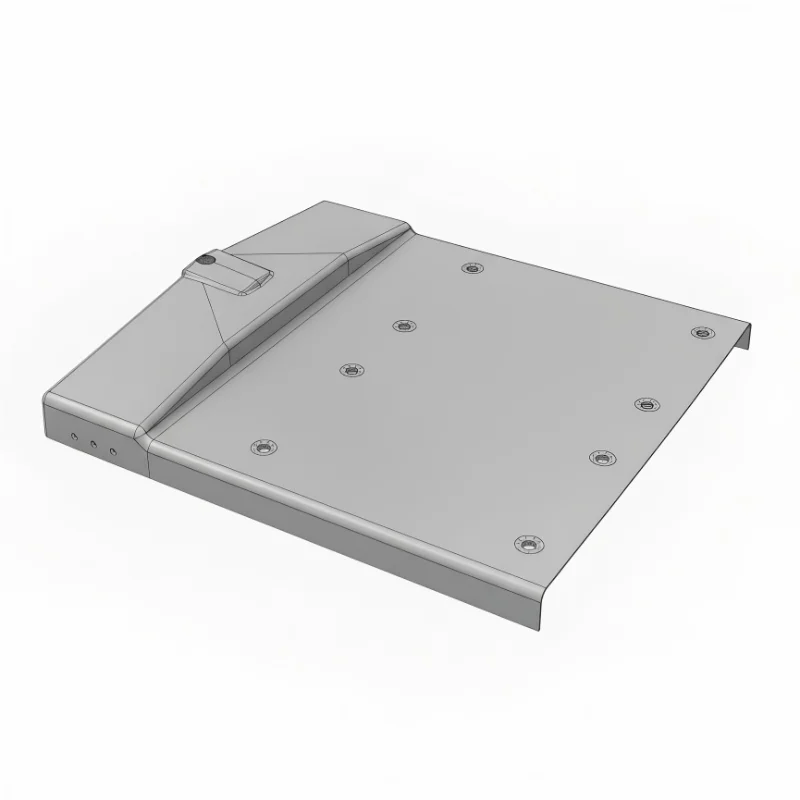

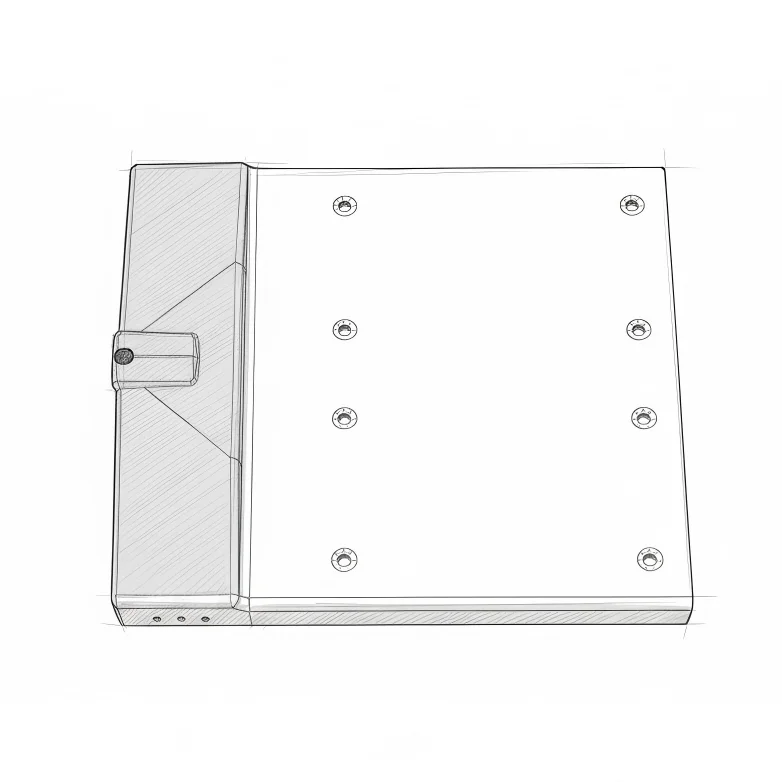

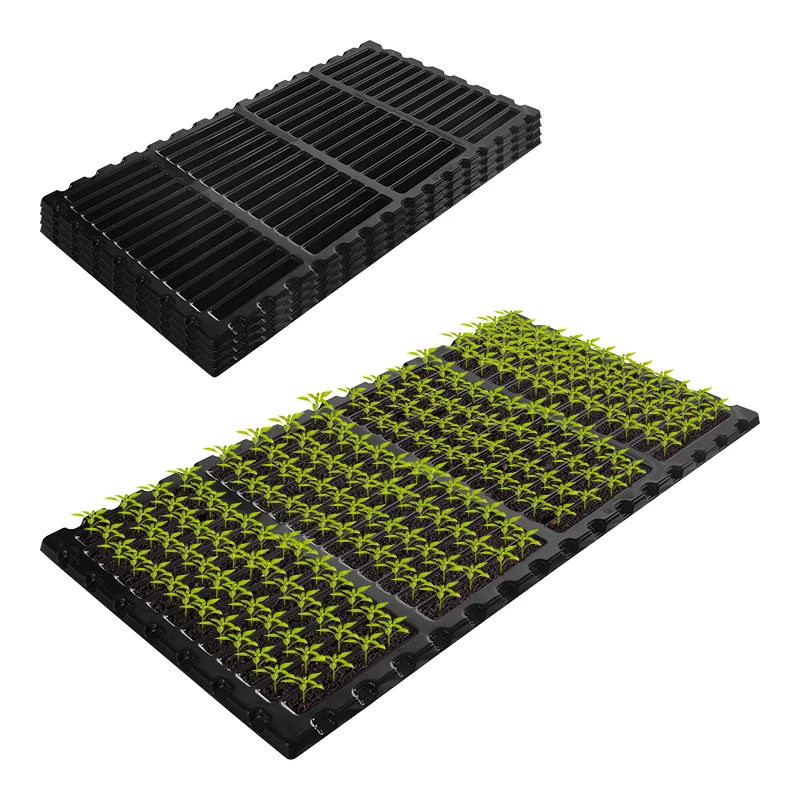

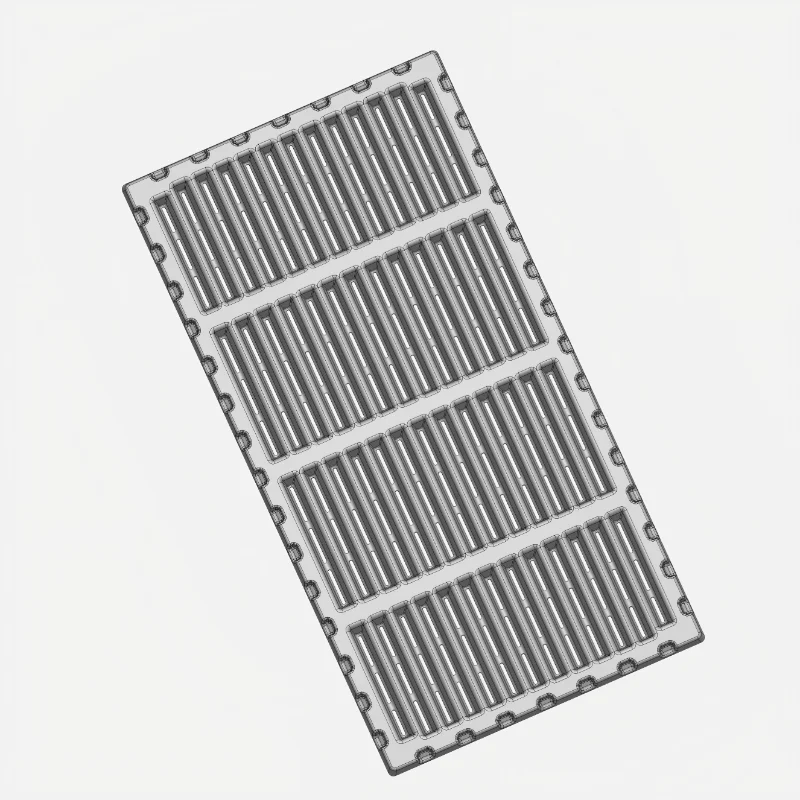

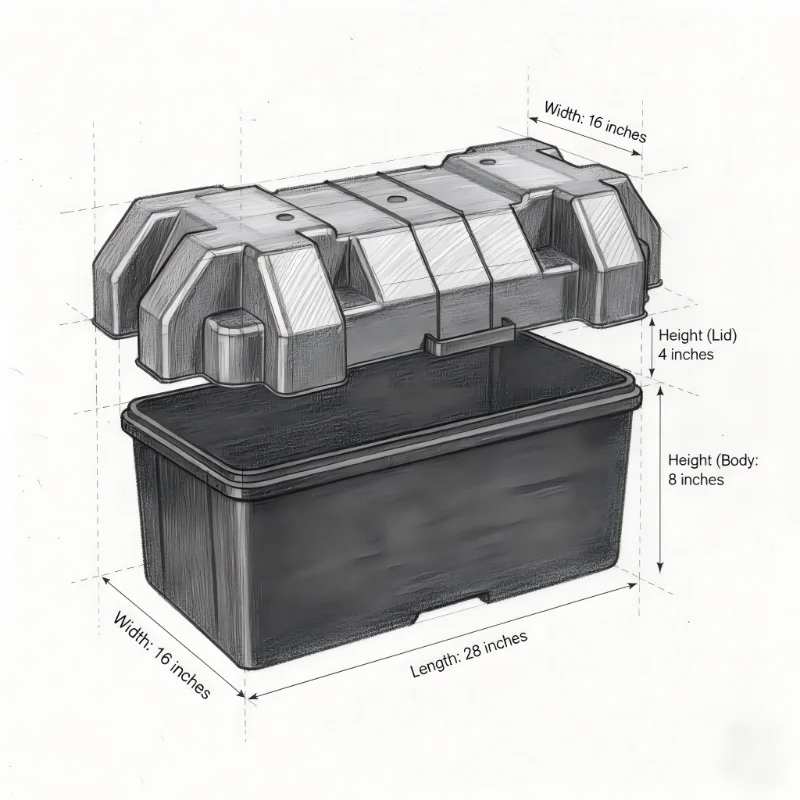

Thermoforming & Vacuum Forming

Specializing in large-scale vacuum forming for industrial enclosures, medical device covers, and structural panels with complex geometries.

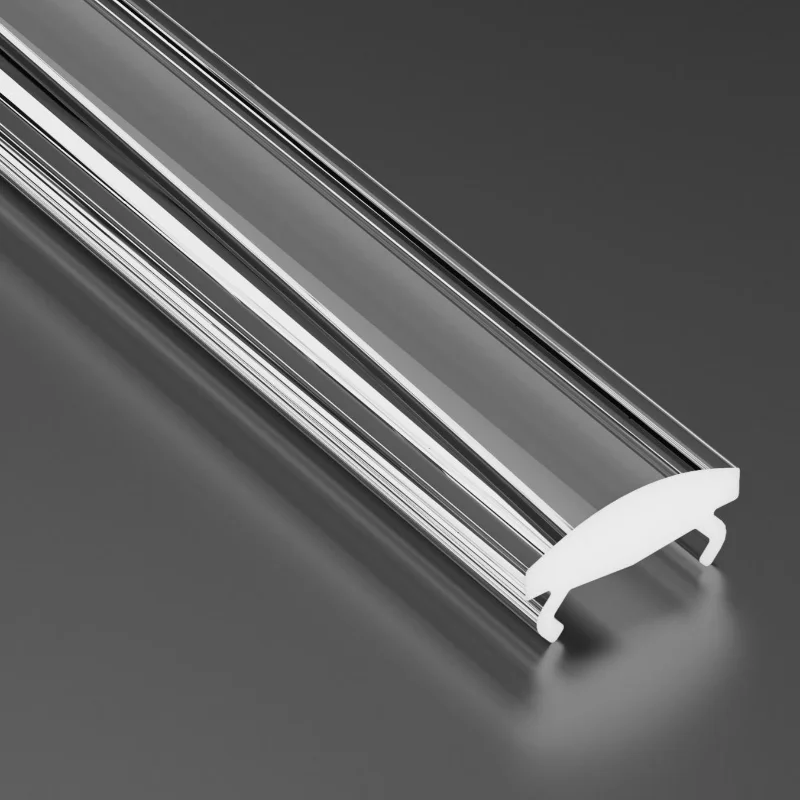

Plastic Extrusion & Custom Profiles

Precision manufacturing of rigid and flexible profiles, industrial tubing, and custom channels with complex cross-sections.

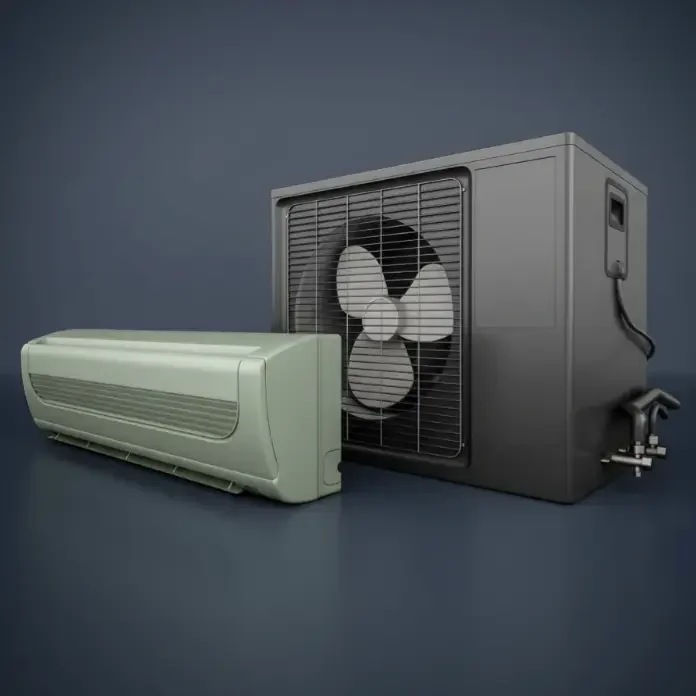

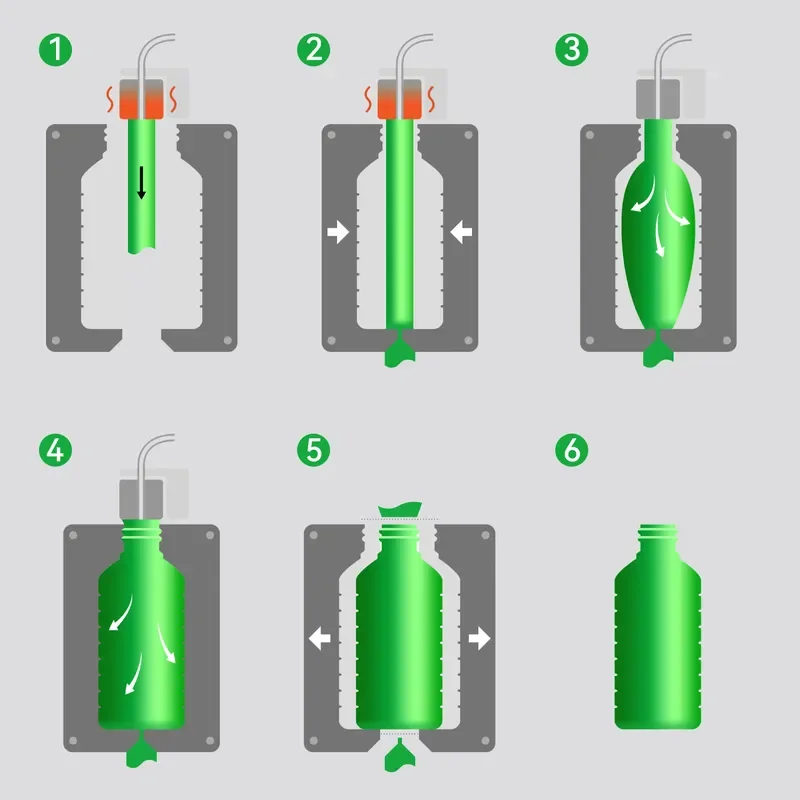

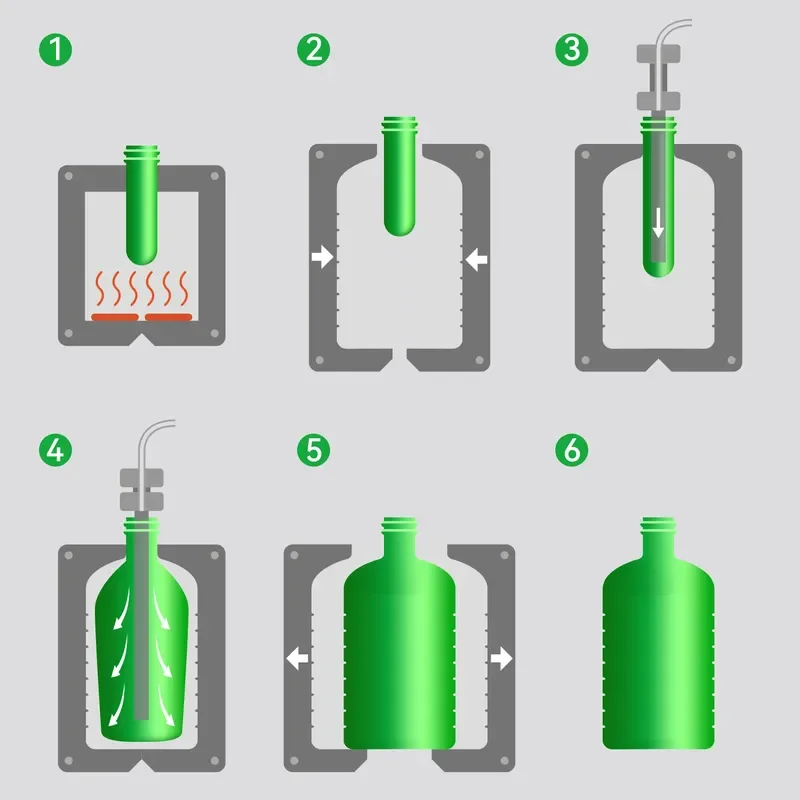

Industrial Blow Molding & Hollow Parts

High-volume production of large hollow parts, custom tanks, and robust double-walled structures for automotive and machinery.