Vacuum forming is arguably one of the most prominent players on the manufacturing stage in the creative field of product design. Its potential to cover many areas of daily production and operations and its rich experience in sustainable development make it the first choice in many industries.

Whether it’s toys, medical devices or electronics, the possibilities are high for vacuum forming to play a role in creating a perfect cosmetic shape, eye-catching smoothness or functional sturdiness.

Making art and leaving physical products as evidence through prolific inventions is a complex process. For example, vacuum forming manufacturing process is a very helpful job in the production of food packaging materials, cups and car dashboards, as well as pizza boxes, jewelry and other products. Vacuum film forming is a very popular thermoforming technology in thermoplastic manufacturing that excels in this area.

In this blog post, we will try to map out the broad spectrum of the entire vacuum forming process at a local level, keeping in mind several important aspects for manufacturers, including the opportunities, features, and benefits that this great technology brings. process. We'll thoroughly analyze each step and illustrate real-life examples while hoping to diffuse the creativity required to utilize vacuum forming to realize these entirely new applications.

Understanding Vacuum Forming Process

Principle of Vacuum Forming

The principle of vacuum forming (also called thermoforming or pressure forming) technology is the process of softening a plastic sheet to the point of elasticity and then covering it on a mold. Finally, the air existing between the plastic sheet and the mold is removed through vacuum pressure. The softened plastic sheet is adsorbed on the mold and is demoulded after cooling to obtain the desired shape. The idea seems like everything is simple until you start working and discover how complicated things can get when you try to personalize it to your needs.

The key to vacuum forming is that if the forming temperature, pressure, or time is not optimal, the process may not succeed properly. Too much heat and the plastic may melt, or not enough heat and it won't form the shape of the mold correctly. The process helps ensure complex product shapes are accurately replicated, reducing overall production costs.

A Brief Overview of Vacuum Forming Process

Heating stage: The thermoplastic sheet is heated in a heating chamber and then molded to the most suitable temperature.

Forming stage: The heated sheet and softened. Next, they are placed into a forming station where vacuum pressure forms them into the correct shape.

Cooling stage: After molding, the new part is immediately cooled to finalize its shape.

Trimming and finishing: Excess material is trimmed and the finished product is ready for further processing or assembly.

Advantages of Vacuum Forming

Versatility: The process is versatile and can handle a variety of plastics and can accommodate a variety of plastic types and thicknesses.

Low mold cost: Vacuum forming molds are relatively cheaper than injection molding molds, making the process more economical for prototypes or low-volume manufacturing.

High-Quality Surface Finish: You can achieve an ultra-smooth surface finish with a smooth mold design and high-quality tooling.

Environmental Protection Advantages

People are becoming more and more conscious about environmental concerns, and modern vacuum forming is proving to be a fairly eco-friendly way to do it. The materials used are used more efficiently, the operating process requires less energy, and many chemicals are recyclable. Therefore, the advantages in terms of economies of scale are significant compared to injection molding.

Notable Product Features Achievable with Vacuum Forming

Where does vacuum forming technology stand out in product design? Here are some great features and products that perfectly illustrate the potential of vacuum forming:

Achievable Product Features

1. Complex Curves and Undercuts

The advantage of vacuum-formed plastics is not only their flexibility in shaping products, but also the ability to create products with complex three-dimensional shapes and undercuts without the complex tooling typically required by methods such as injection molding. Molded housings for drones or car interior parts, for example, with smooth tapered surfaces can be produced using vacuum forming machine (industrial vacuum forming machines, tabletop vacuum forming machines, diy vacuum forming machines).

2. Integrated Textures and Logos

Textures and logos can be added directly to the mold via vacuum forming, which ensures that the final product does not have any observable separation of these features or elements. It is widely used to create brand displays at point-of-sale or signage, embedding 3D fonts through structures.

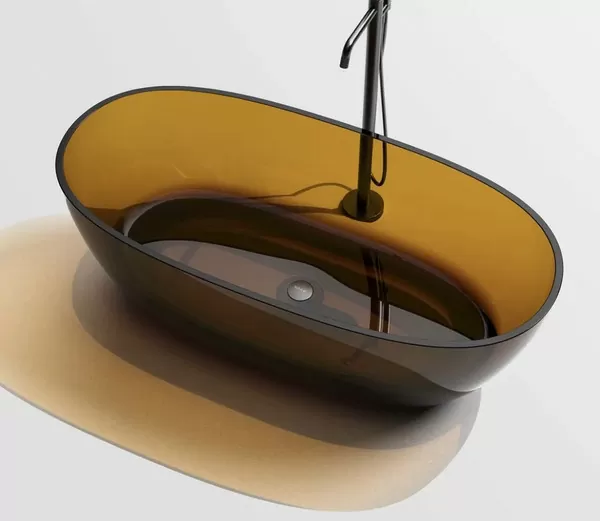

3. Transparent and Translucent Components

Clear plastics are an inherent part of countless product designs, from protective covers for machinery and equipment to the windows of information kiosks and enclosures. Vacuum forming produces uniform, high-definition results that are ideal for these applications.

4. Seamless Large Parts

For larger products or parts, the main challenge is that industrial vacuum forming machines for creating truly smooth surfaces are very expensive. Vacuum forming can give you large vacuum formed parts that have an even distribution of material, resulting in a smooth and uniform surface finish, which is great for applications involving items like refrigerator doors or sectional signage.

5. Prototyping and First Run

First, vacuum forming is cheaper than high-cost technologies. Therefore, building product prototypes and initial production runs becomes the best technique before adopting more complex approaches. Therefore, the engineer or designer will determine whether the proposed design is feasible by conducting experiments on the prototype and save the company the cost of making any major mistakes.

6. Cost-Effective Custom Packaging

Personalized packaging can serve as an important means of advertising and attracting products, ensuring that they stand out from other products on the market. Vacuum forming can create unique packaging inserts, food packaging, trays and clam shells at a lower price than other processes, which adds to the aesthetic attributes of the product without compromising its protection.

7. Aesthetic Customization

The versatility to design and produce unique shapes is considered one of the main advantages of vacuum forming and is another advantage of the process. The process is capable of producing any texture, repeating pattern or profile desired by the manufacturer of the applied product. By using different patterns of molds or the application of textured boards, one can be creative and achieve different yet extraordinary designs.

For example, car parts, from engines and batteries to high-tech features. The plastic parts created through vacuum forming work are almost close to perfect and the dashboard looks luxurious while being able to render the texture of any material like wood grain or leather or anything, which may help the vehicle to be more innovative in terms of appearance. However, this kind of personalization is not only for aesthetics, but also enhances the user experience by incorporating brand elements, allowing for wider sales.

8. Complex Geometry Made Simple

While traditional forming methods may struggle to cope with the complexity, vacuum forming method is booming. This ability to handle complex geometries with ease while maintaining a high level of detail makes vacuum forming ideal for a variety of products, especially those with uneven shapes or undercuts that other processes may find challenging.

One example is the use of vacuum forming in the medical device industry. Specialized enclosures for complex equipment often require a high level of precision and custom assembly. Vacuum forming allows the production of enclosures with internal features and ergonomic considerations that are essential to maintaining the functionality and usability of the device.

9. Lightweight and Durable

There is increasing pressure to reduce environmental degradation and conserve resources. The biggest advantage of vacuum forming products in this regard is the lightness and strength of the products they produce. The main materials used in vacuum forming are thermoplastics that are inherently resistant, as they can be used to create products that are sufficiently strong and durable but at the same time lightweight, thus enabling lower transportation costs and less negative impact on the environment.

An example of this is the successful production in the field of electronics, which contains high-tech products and becomes easy to use. The balance of both elements is crucial, but for a device that users must travel with and wear, the issue of comfort is the biggest design priority.

10. Cost-Effective and Rapid Prototyping

Determining the stages of prototyping is very important in the development of any new product. Its lower tooling costs and shorter cycle times make it a prime choice for cost-effective and rapid prototyping of designs. This fact makes it the best choice for designing prototypes and reacting quickly to the shortcomings of the final product project, much faster than other molding processes.

Imagine a situation where a company wants to know about a product's accuracy and compliance with real-world trials before deciding to mass-produce it. Multiple prototypes can be produced using vacuum forming technology in the time required to manufacture a single prototype using certain standard methods. As a result, the evaluation process will be completed in a shorter time than would otherwise be the case and will result in earlier entry into the market.

11. Large-Scale Production Possibilities

Vacuum forming is great for prototyping, but the speed and affordability it offers also make it suitable for mass production. It is capable of efficiently producing parts of consistent quality, and its operational scalability allows the machine to meet the production needs of a variety of industries, from food packaging to the construction industry.

For ease of understanding, we can look at the application of vacuum forming in the hotel industry. From disposable cups and containers to poolside lounge chairs or more, this approach provides any type of end product that can be manufactured very quickly with short lead times and reasonable costs.

12. The Environmental Consideration

The environmentally friendly features of the vacuum forming process cannot be ignored. The vacuum forming process also reduces the weight of the final product by using less material than other processes for molding materials, and excess material can be recycled again.

The Future of Vacuum Forming in Product Design

As more technologies and plastic materials improve, vacuum forming technology becomes more effective. New heating and cooling technologies have now been developed, and revolutionary plastics and CAD systems have become available. They further push the boundaries in terms of product beauty and reliability.

3D Printing and Rapid Prototyping

The collaborative use of 3D printing and vacuum forming is a favorite among product designers. With 3D printing, complex-shaped molds can be used for rapid prototyping and cheap testing, reducing time per cycle and shortening time to market.

Smart Materials in Forming

With the advent of smart materials, vacuum forming can now produce products with more than just static shapes. Variable stiffness and self-healing materials offer exciting possibilities for dynamic product functionality and increased durability.

Sustainability in Materials and Practices

Furthermore, shifts in this technology, such as the development of sustainable materials with desired properties, are expected to be at the core of such innovations. Second, as vacuum forming manufacturers internationally strive to reduce waste generation, recyclability and reuse will become key factors to consider in the sustainable adoption of vacuum formed products.

The Intersection of Design and Forming

Over time, designers will begin to realize what vacuum forming offers them and will bring about innovation in ways that make sense and are practical. Expect to see more structural innovations and unique surface treatments in the future.

Conclusion

Vacuum forming has proven its value as a long-term technological element in an economically efficient method of manufacturing diverse products. Its competitiveness is sure to increase as industry seeks sustainable and cost-effective alternatives and technology continues to develop capabilities that give it an edge.

Additionally, vacuum forming technology can be beneficial and useful not only to new creators and designers, but also to established ones. The best creations occur when designers can see that there is a vacuum waiting to be filled.

From delightfully unique packaging to enhanced and refined prototype iterations, the vacuum forming process can serve as an image of opportunity, a symbol of the best embodiment of doubt, a sign that explains all that is possible and what is to come.

For product designers and engineers, understanding vacuum forming further enhances their skills, and since this is a never-ending change in the industry, it is their competitive advantage to win in the market. As time goes by, its applications become more and more precise, its products are used in various industries, and its impact on our daily lives becomes deeper and stronger.

The future of vacuum forming innovation may well be a distant realm, but today the garments in this realm are beautiful sheets of plastic that sparkle with charm and have the flexibility and shape to mold into decorative forms of human creation.