Thermoforming is a versatile manufacturing process allowing manufacturers to mold thin and heavy gauge materials. The main principle is to heat and soften the flat hard plastic sheet, then use vacuum adsorption on the surface of the mold, and then form it after cooling. It is widely used in plastic packaging, lighting, advertising, decoration and other industries. Generally divided into heavy gauge thermoforming and thin gauge thermoforming.

Thermoformed products are processed with thermoplastic materials. The product production principle is to heat and soften the flat plastic hard sheet material, then adsorb it to the surface of the mold with vacuum, and then cool it into shape.

Thermoformed products are widely used in the electronics, electrical appliances, and food industries. , hardware tools, cosmetics industry, toy industry, daily necessities industry, medicine, health care products, automobiles, stationery, cultural and sports supplies and other categories of industries.

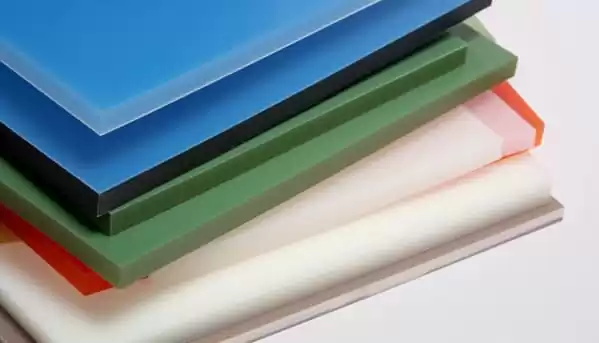

Plastic thermoforming materials usually use thermoplastic plastics, and common ones include polystyrene (PS), polypropylene (PP), polyethylene (PE), polycarbonate (PC), polyvinyl chloride (PVC), thermoformed acrylic(PMMA), polyethylene terephthalate(PET), polyethylene terephthalate glycol(PET-G), high molecular weight polyethylene etc. Different plastic materials have different properties and application areas.

This article will delve into the complexity and artistry of vacuum forming, pressure forming, focusing on a comparison of two common thermoplastic sheets, PC (polycarbonate) and PVC (polyvinyl chloride).

The Difference between PC and PVC Material

Raw Material

The components of PVC material are mostly polyvinyl chloride, which is a general-purpose plastic.

The components of PC material are mostly carbonate-based, which are engineering plastics.

Property

PC material has the advantages of high strength, good transparency, and good impact resistance; relatively speaking.

PVC material is softer, has average transparency, and has inferior mechanical properties to PC material.

Prices

PVC materials are cheaper, typically only half to a quarter of the price of PC materials.

Application

PC can be used as door and window glass, and PC laminates are widely used in protective windows in banks, embassies, detention centers and public places, as well as in aircraft cabin covers, lighting equipment, industrial safety baffles and bulletproof glass.

PVC materials are mostly used in the construction industry, packaging and other industries. For example, PVC materials can be used to make PVC pipes. PVC pipes have the advantages of easy construction, good corrosion resistance, low fluid resistance, good compressive strength, and long service life. We also It can be subdivided into different types such as drainage pipes, wiring pipes, medical pipes, etc. according to their uses.

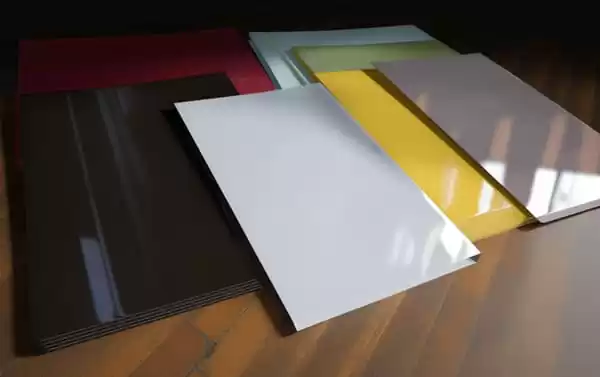

Transparency

PC has high transparency, similar to glass, and can be used to make transparent plastic parts such as eyeglass frames and bottles.

In contrast, PVC has poor transparency and is usually translucent or milky white. Many plasticizers can be added to PVC, and after adding them, soft PVC can be added.

Chemical Stability

PVC has stable chemical resistant properties and is highly resistant to oxidants, reducing agents and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid.

It is also soluble in ethers, ketones, chlorinated aliphatic hydrocarbons and aromatic hydrocarbons. Organic solvents

PC has certain chemical corrosion resistance, resistance to weak acids and neutral oils, and is not resistant to strong acids and alkali. Dilute sodium hydroxide aqueous solution can slowly destroy it, and ammonia, amine or its 10% aqueous solution can cause it to rapidly saponify and degrade.

Mechanical Properties

PC has high mechanical strength, the highest impact strength among plastics, and can even be used as bulletproof material. This clear material forms well and is impact resistant. Its bending and tensile strength is equivalent to that of nylon, and it has high elongation and elastic modulus, but its fatigue resistance is low (less than nylon 66 ), lower compressive strength, better wear resistance (better than ABS), and small creep.

PVC has high mechanical strength, toughness and impact resistance. Its wear resistance at room temperature exceeds vulcanized rubber, and its hardness and rigidity are better than polyethylene.

Heat Resistance

PC Good heat resistance and cold resistance, wide temperature range, can be used for a long time at temperatures of -100℃-140℃, and still has certain toughness at -180℃.

PVC: Thermal stability and light resistance are poor. When it is above 100℃ or exposed to sunlight for a long time, it will decompose to produce hydrogen chloride, which will further auto-catalytically decompose and change color, resulting in a rapid decline in physical and mechanical properties and heat deflection . The use temperature is low (below 60℃)

Characteristics of PC Sheet Thermoforming

It is an amorphous plastic, and the temperatures that need to be controlled are different at different stages.

2) The thermal stability of PC sheet blister is relatively good and can be improved as the relative molecular weight increases.

3) PC sheet blister has good resistance to degeneration and good dimensional stability; but its internal stress is not easy to eliminate.

4) PC sheet blister is easily degraded when exposed to water at high temperatures, and the moisture content is required to be below 0.02% during molding.

5) Cracking may easily occur if care is not taken.

6) During the production process, the apparent viscosity of PC sheets is greatly affected by temperature and less affected by shear rate, and increases with the increase of relative average molecular weight.

7) PC sheet blister has no obvious melting point, the melt viscosity is high, and there are benzene rings in the PC molecular chain, so it is relatively rigid.

Special Processing Method for PC Sheet Thermoforming

Since the blister industry is a relatively new industry, there is currently no textbook-style process solution. We can only summarize relatively suitable processing methods through continuous exploration. In view of the process difficulties of PC material blister, including cracking due to stress, insufficient heating temperature and vacuum strength, and deformation caused by poor cooling, the industry has successively explored some special processing methods.

1) Sheet drying

In view of the fact that PC easily absorbs water, it is generally best to dry PC sheets before heating to absorb the internal moisture.

2) Control mold temperature

We must ensure that the anti-cracking ability and internal stress are balanced so that the cracking phenomenon of PC endurance boards will not occur.

3) Pay attention to molding and cooling time

It is necessary to strictly control the heating forming time not to be too long and ensure sufficient cooling time to prevent the sheet from deforming and curling.

4) Selection of blister machine

For the complex PC blister process, choosing a good blister machine is the first priority.

Characteristics of PVC Thermoforming

PVC sheet has high toughness and is not easy to burn. It will produce chlorine gas when burned, which will have a certain impact on the environment.

PVC is easy to heat seal and can be sealed with a sealing machine and high-frequency edge sealing. It is the main raw material for the production of transparent blister products. PVC sheet is a widely used and popular material.

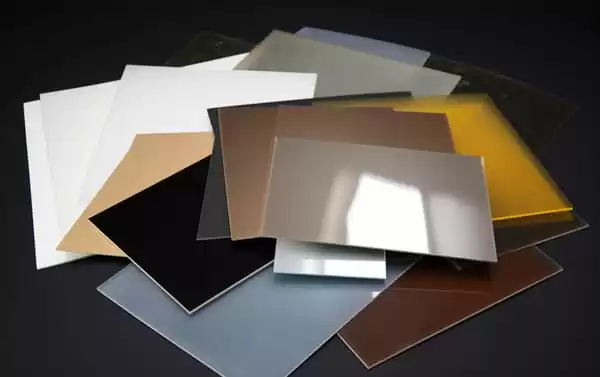

PVC film can be divided into two types: environmentally friendly and non-environmental. It can be made into various blister packaging products such as transparent, colorful, anti-static, gold-plated, and flocked.

The main features are high transparency, good surface gloss, few crystal points, small water marks, wide use, strong impact resistance, and easy to form.

The products are widely used in toys, food, electronic products, medicine, electrical appliances, gifts, cosmetics, stationery, etc. Product outer packaging.

Conclusion

In conclusion, PC sheets and PVC sheets each have their own advantages and their disadvantages, and which one is better mainly depends on the specific use occasions and customerneeds. If you are more care about plastic part's performance and quality (such as temperature resistance, toughness, transparency), you may want to choose PC sheets. If you pay more attention to no pollution or low-cost needs during production process, then PVC may be a better choice.