In the vast field of plastic manufacturing processes, there are several major players: injection molding, thermoforming, blow molding, extrusion, etc. In this article we focus on thermoforming and injection molding. Both have their own advantages and best uses, but if you don't know much about either method, it can feel overwhelming if faced with the need to choose one over the other.

Are you in a business where you make a lot of items that require fine detail? Or do your products tend to be big and simple? Whether you are an entrepreneur navigating the nuances of your first product launch or a seasoned industry player looking to optimize your production line, understanding the differences between these two plastics processing technologies is critical to ensuring the success and profitability of your business.

The manufacturing process of making plastic parts involves using substances that become pliable when heated. There are two main ways to accomplish this: pressing hot molten plastic into a mold (called injection molding) or heating a sheet of plastic and shaping it when it's soft (called thermoforming). These techniques have completely different effects, so you can achieve a final product with unique characteristics depending on how they are made.

In this blog post, we will look at thermoforming and injection molding in detail. We'll compare them based on cost, speed, tooling, aesthetics, size constraints, and scalability factors. By studying these topics in depth enough, you should have a good understanding of both processes—enough to decide which one is best for your own specific needs or project requirements.

Understanding the Basics: Thermoforming and Injection Molding Explained

Before we plunge into the comparative analysis, it's essential to establish a base understanding of both thermoforming and injection molding processes.

Thermoforming

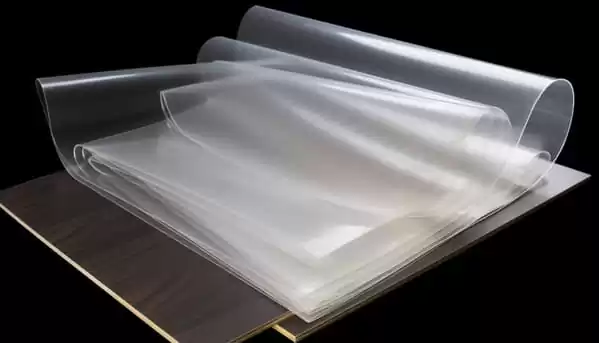

Thermoforming is a cost-effective and versatile technology for converting flat plastic sheets into a variety of shapes. Generally, the process involves heating a sheet of plastic until it becomes soft enough to be formed. The heated material is then draped over the male or female mold and formed into the final shape using pressure or suction (vacuum forming). After cooling again, at which point they retain whatever shape the mold created during the molding cycle, the excess plastic is then trimmed away. This type of application tends to produce larger, shallower items such as pallets.

Injection Molding

Injection molding, on the other hand, is known for making large quantities of intricate parts very accurately and consistently. It starts with small plastic pellets particles of thermoplastic or thermoset resin, heats them until they melt into a liquid/semi-liquid state, and then injects them under tremendous pressure into a mold cavity (or series of cavities). After cooling/solidifying sufficiently so that it retains its shape when demolded, the new molded plastic part breaks away from the original one area; usually no further finishing is required.

Cost Comparison

One of the most significant differentiators between thermoforming and plastic injection molding is the cost associated with tooling and production setup.

1. Mold Cost

Molds for injection molding cost more because the molds are more complex and must withstand high pressures. In contrast, thermoforming typically uses less durable plaster or aluminum tooling, is cheaper to manufacture, and can be produced faster. When starting a new job, the cost of these tools may determine whether it is possible to complete, or whether it requires investing too much money up front.

2. Production Cost

After factoring in the initial cost of the mold building, injection molding each part may become cheaper as production volumes increase. Due to higher production quantities, fixed tooling costs are spread over more units. However, pressure forming is still more economical than injection molding at low- to medium-volume production because it doesn't require extensive machinery to melt and inject the plastic, nor does it require as much energy.

3. Material Cost

Material costs are comparable for both methods, especially if you use standard thermoplastics. However, if a specialty grade is required, the cost may vary based on factors such as availability, disposal methods, and the amount of waste generated.

Speed and Lead Times

Time to market is critical for product introduction, and the manufacturing process plays a pivotal role in this timeline.

1. Thermoforming

Unlike injection molding, thermoforming has shorter lead times because it uses simpler tooling and requires less setup. This makes it ideal for rapid prototyping or low-volume production. Once the production process is relatively simple, it doesn't take long to heated plastic sheet and make parts from it, nor does it take long to get those parts out at the end.

2. Injection Molding

In contrast, injection molding takes longer to set up initially, but can produce parts more quickly once set up. This is useful when you need a large number of the same parts. Once an injection molding machine is set up, it usually doesn’t require constant human supervision—their cycle times and other automated features make them very efficient in this type of work.

3. Tooling Times

Making injection molds can take much longer than a thermoforming mold. This is because the manufacturing process for hardened steel molds is more complex compared to aluminum or composite materials – which are typically used in pressure forming applications where quick turnaround in tooling production helps minimize overall downtime.

Aesthetics and Detail

The level of detail and the desired aesthetics of the final part are critical in choosing between thermoforming and injection molding.

1. Thermoforming

Thermoforming can create textures and undercuts, although its capabilities are not as good as injection molding. Additionally, the surface gloss of a thermoformed product may not be as glossy as the glossy surface of an injection molded part.

2. Injection Molding

The injection molding process is particularly suitable for producing precision parts with intricate details. It can create detailed features, sharp angles, and complex geometries that are impossible to achieve using other technologies alone. Injection molding also allows overmolded or insert-molded parts to be made in a single operation; different materials can also be used together to give the product special properties.

3. Surface Textures

The surface quality of the final product may be affected by the ability of both methods to create different surface textures such as textures, patterns, or custom finishes. The surface quality of the finished part is severely affected by the surface treatment of the mold during thermoforming, while injection molding relies on high-grade steel to achieve the same purpose.

Part Geometry and Material Thickness

When it comes to the types of parts each method can produce, thermoforming and injection molding tout their own strengths.

1. Thermoforming

Thermoforming, with its ability to produce parts with uniform walls and features such as holes and flanges, is ideally suited to meet these needs. So you can make large shallow parts, or use special methods to make deep drawn parts.

2. Injection Molding

No other manufacturing process can match the capabilities of injection molding when it comes to handling complex shapes and varying wall thicknesses in the same mold. This flexibility is crucial for producing parts that must withstand stress or air pressure, as injection molding can reinforce areas or add lightweight sections only where needed.

3. Size Consideration

Thermoforming is advantageous for larger parts because its heating station is large and the sheet is easy to process. In contrast, injection molding machines have size limitations, as well as limitations based on how the mold opens (thereby limiting the geometry of oversized parts).

Environmental Impact and Material Waste

With environmental concerns growing, the sustainability of manufacturing processes is an important consideration.

1. Thermoforming

Thermoforming creates less waste when producing a product because any remaining material in the flat sheet is most of the time cut out and reused. Additionally, this method uses less electricity overall—it relies primarily on heat and a pressure/vacuum system for forming purposes.

2. Injection Molding

Injection molding is more energy-intensive because it requires heating the barrel to melt the plastic and applying force to inject it into the mold. However, contemporary machinery used for this purpose emphasizes using less energy per production cycle while achieving overall high efficiency; furthermore, by employing advanced designs of the mold itself or the channels (runners) through which the molten material flows, significant reductions can be achieved waste.

3. Material Recycling

Both thermoforming and injection molding processes can utilize recycled materials; however, their ability to incorporate such content depends on the part specification and the type of plastic involved. In both cases (thermoforming injection molding), post-industrial or post-consumer recycled materials can be used when manufacturing the product, the latter being more common in injection molding due to material purity requirements.

Quality Assurance and Certification Requirements

In certain areas, the quality and certification of production components can have a significant impact.

1. Thermoforming

To meet tight tolerances and quality requirements (such as during CNC trimming or surface finishing), additional processes may be required when manufacturing vacuum formed parts.

2. Injection Molding

The ability to manufacture parts repeatedly, time after time, with little variation from part to part is one of the main advantages of injection molding. This makes it particularly suitable for manufacturing products such as medical or automotive industry components that must be certified, as they often fit together perfectly.

3. Regulatory Compliance

The decision between these two manufacturing processes will be influenced by any regulatory standards that the product must comply with. Material purity, durability, and aesthetic standards are examples of requirements that may be more appropriate for one process than another.

Conclusion

When deciding whether to use thermoforming or injection molding, it's not as easy as choosing just one or the other. Both have their advantages – if you want what works for your project (and saves you money), understanding it inside and out is key.

If you need help making a decision, think about what you want to get from the parts: How much do they cost? When must it be delivered? What is their size or shape (if important)? Is it important to go green and other factors that are personally/professionally important. It is also helpful to consult with manufacturing experts who can provide tailored advice based on experience with similar projects.

Ultimately, choosing between thermoforming and injection molding depends on your project needs. If getting things done quickly or cheaply is important, or if being able to use a large number of different materials is key, then one manufacturing process will be better suited than another. By weighing these pros and cons while also considering exactly what it is you are trying to achieve with this particular job - it should be possible to make an informed decision that will ensure success when producing plastic parts.