In manufacturing, being efficient is essential for success. This is especially true in thermoforming, where finding methods to shorten production time can make a big difference – whether you’re making car thermoformed parts, medical equipment or food packaging. Increasing profitability and keeping clients happy becomes much easier if you can improve how thermoforming works.

Efficient thermoforming production involves more than just time-saving techniques. It’s also important to make each step count by being accurate and necessary. By adopting this mindset, you can shorten lead times, minimize waste during manufacturing—and end up with an high volume production.

Thermoforming Process

Thermoforming turns a level plastic sheet of plastic into useable products. It does this by heating the plastic sheet until it’s malleable, shaping it using a mold and cutting away any excess material. Although it seems straightforward enough when broken down into these steps, there are many complex variables – as well as possible obstacles – that come into play at every stage of production.

Every aspect is crucial to how well the operation runs – from materials chosen, how tools are designed and heating processes, through to finishing touches once production is complete. But if we want to speed up any of these things, where should we begin? And can we do it without affecting the standard of the end product?

Challenges in Thermoforming Production

When it comes to efficiency, Thermoforming has many hurdles. The heating and cooling steps hog time and energy. On top of that, changing molds, loading materials and trimming parts all add to how long the process takes overall. Plus, the quality standards and mechanical properties of the final product cannot be compromised for the sake of speed.

Material Costs: Choosing the Right Substrate

Want to speed up production time? Start with your material choice. For vacuum forming projects, the type of resin you use affects how fast, how well and at what price your product can be made. Here are some things about materials to think over:

1. Pre-Colored Materials

Opt for pre-colored plastic sheets that don’t require painting or another finish. This way, you won’t need to wait for them to dry – or do anything extra at all! It also saves time because there are fewer steps overall.

2. Thin-Gauge Materials

If you use thin-gauge plastic sheets for thermoforming, you can speed up how they heat and cool. Because there’s not much material to them, they don’t take as long to form or require as much energy – plus they also transfer heat faster than thicker alternatives.

Material Handling Efficiency

1. Material Mishaps

A problem that can ruin your plans for making things by heat-shaping plastic is if the materials aren't handled correctly. Dust, water and static electricity are often to blame when shapes don't form properly. It's also important to organise how materials are kept and moved to and from the heat-shaping machine so they don't get broken or hold up production.

2. Best Practices for Material Efficiency

Have strict rules for where materials are stored, like in spaces with humidity controls that get cleaned regularly. Use tools and products that prevent static electricity from building up on things – which can make them sticky or dirty. And think about making robots do more of the work when you're shifting items around, so mistakes are less likely and everything happens faster.

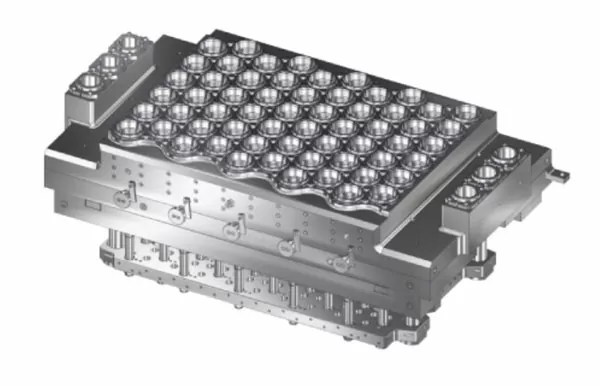

Mold Design for Efficiency

If you want your thermoforming process to be quick and produce high-quality results, don't overlook the importance of good mold design – including trim fixtures. Here are some tips for boosting efficiency:

1. Fast-Cycle Mold

Consider purchasing durable, high-quality mold that can handle rapid production without wearing down. Using better materials and designs for your mold could mean you get more uses out of it before it needs maintenance – which keeps thermoforming equipment running.

2. Simplified Mold

If you can, look into buying a mold design with fewer mold sections. This might cut down on how long it takes to switch molds between manufacturing batches.

3. The Foundation of Quality

For thermoforming businesses, problems with tooling and mold design can be a major setback. If your molds, dies, or trimming tools are not up to scratch, you might end up with low-quality products – as well as longer production cycles and wasted materials.

4. Next-Generation Tooling Solutions

Investing in strong, reliable tooling technology will help you work faster and more efficiently.Cutting-Edge Tooling SolutionsWhy not try 3D printing? It’s great for making prototypes quickly or tweaking designs.Make sure everyone’s into the swing of regular tooling maintenance and inspection – it makes such a difference. You could also investigate self-healing materials (yes, they really exist!) plus coatings that last well and make maintenance easier: both could extend the life of your molds considerably.

Optimize Equipment Setup Times

1. The Lean Mindset

If you want to make your operation more efficient, start by closely examining how things are currently done. It's important to embrace the principles of lean manufacturing at this stage. Look for any unnecessary movements, materials or steps in your pressure forming process – such as tightening bolts too much or not heating plastic sheets as well as possible. Even small things can add minutes or hours to changeover periods when they happen repeatedly during a shift.

2. Techniques That Work

Invest in quick-change tooling and equipment designs.

Train staff in Single Minute Exchange of Die (SMED) techniques for rapid changeovers.

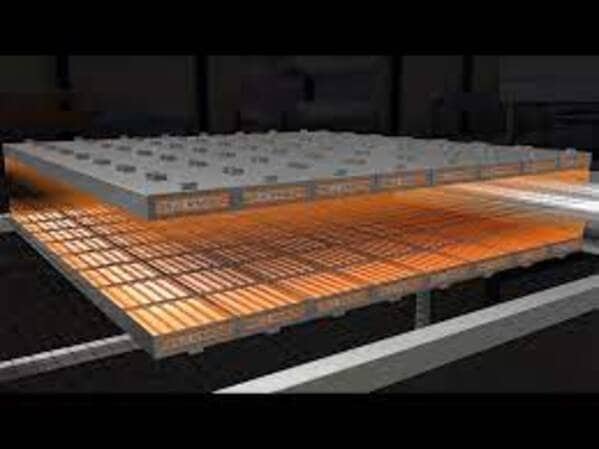

Heating Strategies: Consistency and Speed

When thermoforming, it's important to heat the material evenly and fast so that it reaches its optimum temperature for shaping. Ways to do this include:

1. Inline Heating

Consider inline heating processes that eliminate the need to move the plastic sheet to a separate heating unit. This saves time when making big plastic components.

2. Reflective Systems

Make heating more efficient by bouncing energy off reflectors. More warmth goes where it’s needed (into the material) and less heats up the air or machine around it. This can also shorten cycles.

Precision Temperature Control

1. The Impact of Heat

Thermoforming quality relies on exact temperature control. Even slight changes can cause imperfections and waste, meaning things must be redone or fixed. You need to be consistent. But if you only focus on making it really hot – which might seem important – then you could end up with problems like breaking molds or making the material get old too fast.

2. Keeping Temperatures in Check

Implement advanced temperature monitoring systems that offer real-time feedback and automated adjustment capabilities.

Perform regular maintenance on heating elements and assemblies to ensure uniform heat distribution.

Invest in specialized training for operators to recognize and react to temperature variations before they impact production.

The Forming Process: Speed and Control

The material is shaped using either vacuum, pressure or both. Making tiny changes here can mean big time savings later on:

1. Process Monitoring

Have automated systems keep an eye on how the shaping is going, then tweak things as needed in real-time. That way production stays smooth without sacrificing quality or consistency.

2. Rapid Tool Changes

Where applicable, implement quick-change tools that can be swapped out in a matter of minutes, allowing for rapid shifts between different final products or final shape.

Trim and Finish: Quick and Clean

Once forming, thermoformed parts need to be trimmed and completed. This step can sometimes cause delays in production – although it doesn’t always have to. Here are some options to consider:

1. Automated Trimming

Use robots at trimming stations. They work fast and don't make mistakes like humans do when they're tired or bored. Plus, you won't need as many people on this job if it’s automated.

2. Simultaneous Operations

Look into ways of doing the trimming and finishing at the same time as forming. Two examples are “in-mold trimming” (cutting off excess material while stuff is being shaped) and “mechanical clamps” (using metal bits to grab and yank off extra fast).

Post-Processing: Integration and Innovation

When thermoformed parts are shaped and cut, there might still be more work to do. Post-processing can be sped up through innovation and integration:

1. Modular Assembly

With Modular Assembly Design, components fit so well you don’t need extra screws or glue – which saves time and makes things simpler overall.If you can check quality at the same time as doing something else, it speeds everything up.

2. Online Quality Control

Conduct quality checks inline wherever possible. Modern inspection equipment can quickly identify defects, allowing for immediate correction and keeping faulty parts out of the final product stream.

Harnessing Data: The Power of Analytics

In a high air pressure production setting, information is invaluable. It can reveal weak spots and point you toward better ways of working:

1. Production Monitoring

Keep tabs on how well your equipment and workers are doing, so you can spot trends, plan fixes before things break down – and fine-tune systems to get as much out of them as possible.

2. Lean manufacturing Principles

Do more with less; keep getting better: Look into lean principles for manufacturing. One good move is using info to find where improvements are needed – or possible.

The Human Element: Training and Empowerment

In the end, whether or not your efforts to increase efficiency actually work will depend on your employees. However, if you invest in their well-being and development, it can help improve both how quickly things get done around the office as well as overall work quality. There are a few different ways to do this:

1. Ongoing Training

By providing regular professional development opportunities, you enable workers stay current with any new tools or methods that may come out – meaning they’re more likely catch inefficiencies before they become major problems.

2. Empowerment

Empower your team to make suggestions and take ownership of their part in the production process. They are often the best source of what can be improved and how to do it.

Explore Automation and Robotics

1. The 24/7 Workforce

In a business where any idle time results in lost money, having automation and robotics systems gives you an edge that cannot be beaten. They can do things like move materials around or take finished parts off the line better than people can – faster and more accurately. This means your thermoforming line can run at its best non-stop, 24/7.

2. Introducing Robotics to Thermoforming

Begin with simple, repetitive tasks and gradually introduce more complex automation processes to build confidence and experience within your team.

Collaborative robots ("cobots") can work alongside human operators, assisting with heavy lifting and other physically demanding tasks.

Maintain a flexible mindset, understanding that while automation can significantly reduce production time, it may require periodic reconfiguration to accommodate new projects and changing market demands.

Conclusion

Efficiency is essential in manufacturing – it’s not enough just to be good anymore. To reduce thermoforming production times, you need to take a 360° look at everything involved. By fine-tuning heating, materials, tooling, forming and finishing; speed increases are possible – as is higher quality output that may leave others trailing in your wake.

In order to succeed in vacuum forming production, it is essential to constantly seek ways to improve. This means always being open to new ideas, investing in the latest technology and making sure employees feel valued. By striving for excellence in this way, companies can make their manufacturing processes quicker – something which matters a great deal in this sector. And as an added bonus: both customer satisfaction levels and profits tend to go up when firms adopt this kind of approach!

Efficiency in thermoforming production is not a coincidence. It comes from making constant and conscious efforts in every aspect of the business. By following these strategies and promoting an environment where everyone always tries to do better, your thermoforming company can become more efficient than ever before. This will mean shorter production times –– but also so much more. You'll be set up for growth because you'll be able to innovate; plus, you'll outperform competitors when it comes to both the quality of what you produce and how often you can send it out. Don't forget: The aim here is not just to finish faster than before. It's about providing an improved product that customers can rely on –– every single time they order from you!

Several key strategies are emerging as important in the drive to make thermoforming production more efficient. One of these is looking at what advantages injection molding may bring because it is known for being both precise and efficient. By managing things such as how thick wall thickness are, it becomes possible to both speed up the time taken on production cycles and use materials better – so they cost less overall.Another thing that needs to be thought about a lot is the idea of glass transition temperature: getting substances to the right point for shaping without losing how strong they are. Using a female mold can also help speed things along by providing an easier way to shape substances.

When it comes specifically to metal molds (which are great because you can rely on them over time), selecting materials that strike a good balance between durability and quickness is very important. If not managed correctly, brittle plastic could mean your efficiency doesn't stack up.Lastly, one must think about factors like chemical resistance both for how long molds will last and making sure products come out right. By using these techniques and taking these points into account manufacturers can cut down how long it takes for thermoforming – but still do a good job; their items will also work well when bought new further down the line too.