Three Processes.

Infinite Solutions.

ZetarVac is a global leader in Integrated Plastic Manufacturing Solutions. We combine Heavy-Gauge Thermoforming, Custom Plastic Extrusion, and Precision Blow Molding to deliver one-stop manufacturing excellence.

Production Lines

Thermoforming, extrusion, and blow molding lines ready for scale.

Molds Per Month

Rapid tooling capabilities across all three manufacturing processes.

Materials

Expertise in Kydex, ABS, HDPE, PC, PP, PVC and high-performance blends.

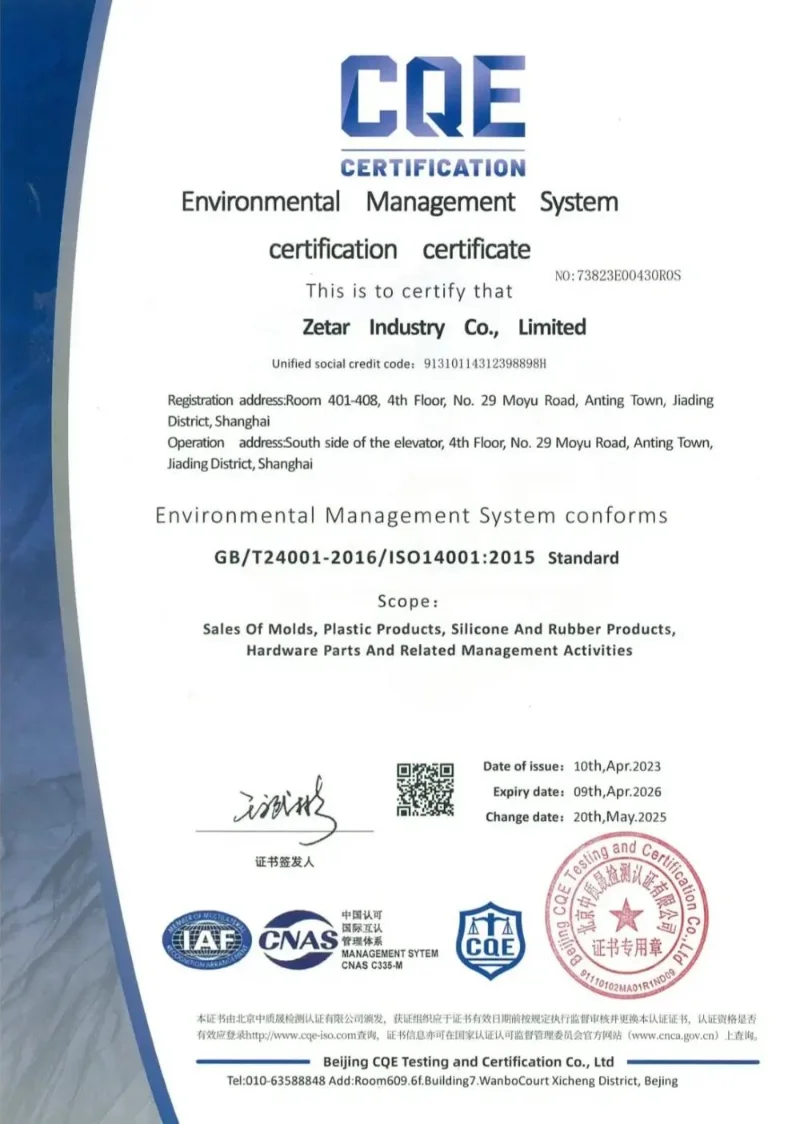

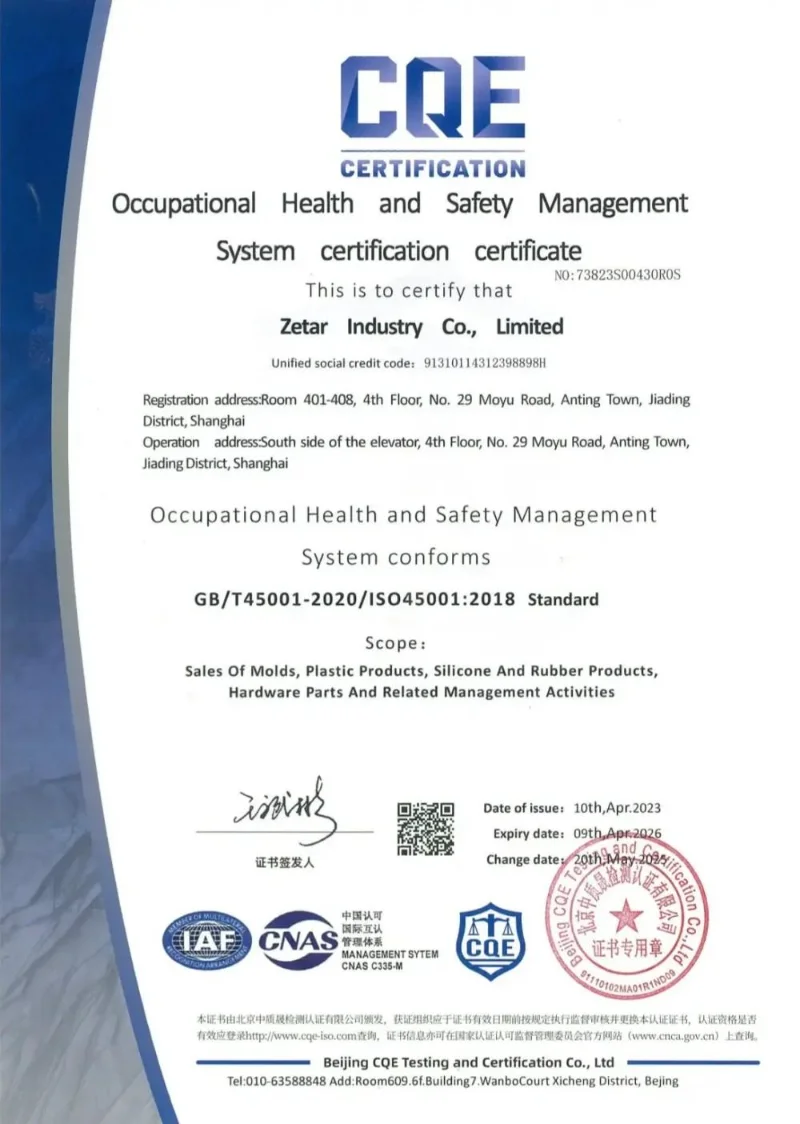

Certified Quality

ISO 9001, 13485 (Medical), 14001, and 45001 certified.

Who We Are

More Than Just a Manufacturer.

We Are Your Total Solution Partner.

At ZetarVac, we have built our reputation on being the stable, authoritative partner for global enterprises requiring integrated plastic manufacturing solutions.

Unlike traditional manufacturers limited to a single process, ZetarVac offers three core technologies under one roof: Heavy-Gauge Thermoforming for structural components, Custom Plastic Extrusion for continuous profiles and tubing, and Precision Blow Molding for hollow parts and containers. This integrated approach eliminates the need for multiple vendors.

- Thermoforming Excellence: Heavy-gauge structural components and precision enclosures.

- Extrusion Mastery: Custom profiles, industrial tubing, and complex cross-sections.

- Blow Molding Precision: Large hollow parts, tanks, and double-walled containers.

- Process Selection Expertise: Unbiased guidance on choosing the optimal manufacturing method for your specific part geometry and volume requirements.

Core Technologies

One Partner. Three Processes.

Our integrated approach combines the best of thermoforming, extrusion, and blow molding to deliver optimal solutions for any plastic manufacturing challenge.

Heavy-Gauge Thermoforming

Structural integrity for demanding applications. From massive industrial covers to intricate medical device enclosures, our thermoforming capabilities handle thick-gauge materials with precision.

- • Material thickness: 0.5mm - 15mm

- • Kydex, ABS, HDPE, PC specialization

Custom Plastic Extrusion

Continuous-length profiles and complex cross-sections. From industrial tubing to architectural trim, we extrude rigid and flexible materials to exact specifications.

- • Rigid & flexible extrusion

- • PVC, PP, PE, TPU materials

Precision Blow Molding

Hollow parts and containers with superior strength-to-weight ratios. From large industrial tanks to complex double-walled structures, we deliver precision hollow components.

- • Double-wall capabilities

- • HDPE, PP, PET specialization

Our Infrastructure

Take a look inside our state-of-the-art facility. From massive thermoforming machines to precision extrusion lines and blow molding stations, we are equipped for integrated manufacturing at scale.

Quality Assurance

Certified for Excellence

Our commitment to quality is backed by international standards. We maintain rigorous compliance across all manufacturing processes for medical, aerospace, automotive, and industrial applications.

ISO 9001

Quality Management System

ISO 13485

Medical Device Quality

ISO 14001

Environmental Management

ISO 45001

Occupational Health & Safety

Ready to Scale Your Production?

Leverage our 60+ production lines and integrated manufacturing expertise for your next project. Whether it's thermoforming, extrusion, blow molding, or a combination of processes, we deliver.