If you’re considering thermoforming for your project, take note: thermoformed sheets come in many thicknesses. That’s because this versatile process can be used to make everything from food packaging (think: yogurt cups) to vehicle door panels. And different products often require different material thicknesses too.

Want to make sure your thermoformed products look great and work perfectly? One thing you might not think about is how thick the plastic sheet should be when you’re shaping it. It can’t be too thin or too thick if you want to get it just right. We’ll tell you everything you need to know about choosing the best gauge (that’s how thickness is measured) for successful thermoforming; whether you’re going for beautiful packaging that shows off your design skills or tough vehicle parts that won’t break when they’re needed most. In this blog, learn how to choose the right plastic material gauge to achieve peak functionality, form, and aesthetics in your thermoformed products.

The Role of Material Thickness in Thermoforming

The properties of a thermoformed product are influenced by its thickness. This includes everything from how strong and resistant to damage it is, through to the surface finish and even weight. Knowing what thickness range is best for these factors is important if you want your products to be good quality – but also if you want to make them economically using thermoforming!

Structural Integrity & Impact Resistance

Thicker sheets provide enhanced structural support and higher resistance to impacts, making them suitable for products that require durability, such as casings for electronic devices or protective covers for machinery.

Surface Quality

Items such as electronics or packaging look better if they have fine finishes. To achieve this, thermoforming use materials that can be made into smooth surfaces without lots of expensive polishing – sometimes by using very thin sheets of the material.

Weight Considerations

Many industries now prefer lightweight products because they are cheaper to transport, use less fuel and are easier to manage. By using thinner sheets or materials that are still strong enough – so they don’t break or fall apart – manufacturers can make final products that weigh much less.

Maximum Sheet Thickness

Thermoformed sheets are usually no thicker than 0. 5 inches (12. 7 mm). However, such thickness is less common. It tends to be for heavy-duty jobs needing extra-strong parts: think car bits, big machinery elements and some equipment housings. Thermoforming sheets of this thickness are generally referred to as thick-gauge thermoforming.

There are times when thermoforming requires using the thickest possible plastic material. This is especially true for certain products that need to be strong or have a lot of depth. Here’s why you might choose thicker plastic – and what advantages it can offer.

Maximum Material Thickness: When to Go Thick

1. Deep Draw Thermoforming

If you want to make big plastic items using deep-draw techniques – and ones that don’t have any thinning or split when you’re shaping them – you’ll need to use plenty of material and heavy gauge plastic sheets.

2. Heavy-Duty Industrial Components

If you need components that can handle tough industrial conditions, you definitely want ones made from heavy-gauge materials. These materials provide unmatched durability—they resist damage and wear from rough use much better than other types do.

3. Large-Scale Products

Products such as bathtubs, truck bed liners, and specific vehicle parts require thicker plastic in order to hold up well with use — particularly over large areas — and continue working correctly.

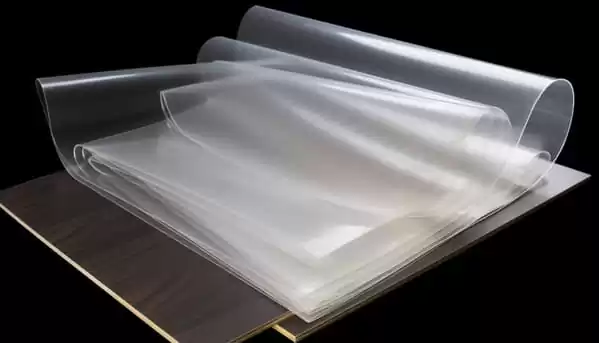

Minimum Thickness

On the other end of the spectrum, thermoformed sheets can be as slim as 0. 014 inches (0. 35 mm) during thin-gauge thermoforming—often used for disposable cups, lids, trays, containers, and other packaging items. Rapid production and cost-effectiveness through material usage are benefits to thin-gauge thermoforming; important considerations in an industry focused heavily on being profitable such as packaging.

Discover the Art and Efficiency of Thin-Gauge ThermoformingExplore how this technique allows manufacturers to craft delicate, detailed items with accuracy – all while saving money.

Minimum Material Thickness: Thinning for Precision

1. Cost Savings

Thinner sheets save money on buying them and also mean that heated sheet and shaping takes less time – so you use less energy for this part of the process, and products get made more quickly as well.

2. Detailed and Complex Shapes

If you’re looking for intricate designs and fine detail, thin-gauge materials are the way to go. These can better capture the nuances of a mold and tool surface—meaning they produce highly detailed items that also look good.

3. Flexible Packaging

Thin-gauge thermoforming has played a major role in the popularity of flexible, see-through packaging within the food, retail and medical industries. This type of material provides an excellent barrier to protect products as well as good visibility for consumers.

Factors Influencing Thickness Choice

Several factors determine the appropriate thickness for a thermoformed product, including:

Durability Requirements: Heavier, more durable items need thicker plastic material.

Flexibility Needs: Flexible items, such as certain types of packaging, may benefit from thinner materials.

Mold’s Contours: The complexity and depth of the mold can require adjustments in plastic material thickness to achieve the desired detail and structural integrity.

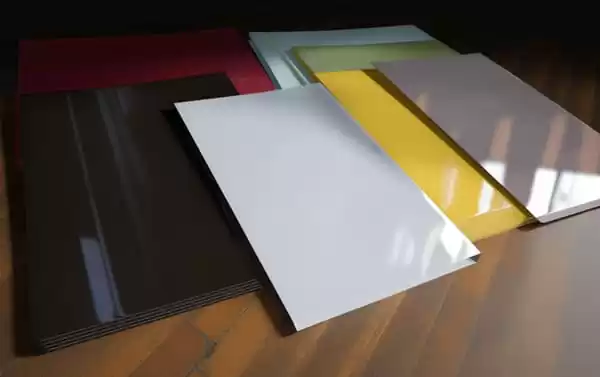

Material Type: Different plastics have varying strength and flexibility characteristics, which can affect the optimal thickness for a given application. Commonly used materials include ABS, polystyrene, polyethylene, and PVC.

Striking the Right Thickness Balance

To find the best thickness for vacuum forming process, you must think strategically. Consider what you need to make, how it should look and how much you can spend – then balance everything up just right.

Understanding Product Requirements

A thorough understanding of the product’s end-use environment, expected life cycle, and functional requirements is crucial for identifying the appropriate plastic material thickness.

Design Impact

If you want design features like undercuts or deep draws, require thicker sheets so they don’t get distorted. On the other hand, if your product has lots of intricate details or a complicated shape – something finely sculpted, say – thinner materials often work better all round.

Cost vs. Quality

Finding the right balance between plastic material cost, production quality, and speed is a delicate trade-off. While using thin-gauge materials can save money, there is a risk: if they are not suited to the job they could cause products to break – meaning extra work (and expense) having to fix them.

Industry Use Cases: Material Thickness in Action

Thermoforming has multiple uses and isn’t limited to just one industry. Depending on the sector, different standards and requirements apply –– meaning plastic material thickness is crucial.

Health and Safety Equipment

Items such as safety helmets require thick-gauge materials in order to provide effective protection against high-impact incidents. However, many face coverings designed for personal protection employ thin-gauge materials—so wearers can breathe easily and hig clarity.

Consumer Electronics

The slim and intricate styles of electronic casings mean that thin-gauge thermoforming is preferred. This produces lightweight products which are high in quality and provide protection for delicate internal parts.

Transportation

In the transportation industry, a mix of different materials is used to make vehicles. Thick-gauge materials are chosen for strong parts like car bodies, while thin-gauge ones are used inside cars. These lighter materials can still stand up to wear and tear – and help cut down on weight too!

Material Selection: Considerations Beyond Thickness

While thickness is a critical component in material selection, it’s not the only consideration. Material properties, such as tensile strength, UV resistance, and chemical compatibility, also influence the performance of the thermoformed product. Such as PC, PVC, PET, PET-G, Acrylic Sheets.

1. Material Compatibility with Mold Temperature

It’s important to know how different materials behave when they are being thermoformed because some may need a optimal forming temperature in the mold to work their best.

2. Environmental Impact

When you want to be sustainable, you have to think about using materials that excess plastic can be recycled or will break down naturally – but you also have to make sure they do what your product needs!

3. Customer Preferences

Identifying customer preferences, whether for premium finishes provided by thin materials or rugged durability from thick-gauge forms, guides the selection of the most appropriate material for the project.

Advanced Techniques for Material Adaptability

To push the boundaries of what’s achievable with thermoforming, try some advanced techniques. For example, there’s twin-sheet forming and pressure forming. You can also use composite materials that let you combine different thicknesses and properties – so you get the best of everything.

1. Twin-Sheet Forming

Using two thermoplastic sheets, this method forms a hollow object – giving designers more scope for creating shapes while also making the structure stronger.

2. Pressure Forming

By heated plastic sheet and squashing the material together through air pressure, pressure forming produces parts with an even thickness all over and fine details, making it suitable for products that require a premium finish.

3. Custom Material Composites

Developments in technology mean companies can now make composites (materials made from more than one type of stuff) that have specific properties, such as a thin top layer for aesthetics and a thick substrate for strength.

Conclusion

As you decide on a thickness for your thermoformed sheet, keep in mind how this choice affects not only quality and functionality but also cost – both during manufacturing and afterwards. To get it right, familiarize yourself with material properties, vacuum forming processes and what the product will be used for. Talking to an experienced materials engineer or manufacturer can help make sure the thickness you pick does everything you need it to do while maintaining efficiency and cost-effectiveness.

Selecting the right thickness for thermoforming is more than a technical choice—it embodies the intersection of art and science in manufacturing. Once you’ve got this this balance, you can make goods that don’t just look good and sell well—they’re also long-lasting and inexpensive to produce. So keep pushing at the boundaries of material science. Because whether you’re working in electronics or food processing, you’ll discover that perfect place for thermoforming.

By utilizing precision, attention to detail, and an understanding of the thickness of materials used, in addition to injection molding, you can also take advantage of thermoforming. Armed with this knowledge, you can push your thermoforming capabilities further than ever before – meaning more innovative products and better quality too. Appreciating how material thickness affects what you end up with isn’t just important for any kind of progress in thermoforming; it’s vital! Because without getting it right when it comes to how thick things need to be, there won’t be any successful projects done via this process at all.